Page 31 - PWM2025_AUGUST EBOOK

P. 31

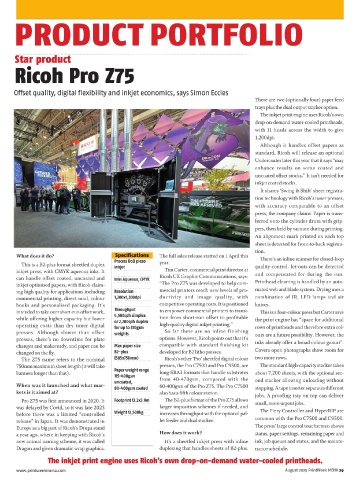

PRODUCT PORTFOLIO

Star product

Ricoh Pro Z75

Offset quality, digital flexibility and inkjet economics, says Simon Eccles

There are two (optionally four) paper feed

trays plus the dual output stacker option.

The inkjet print engine uses Ricoh’s own

drop-on-demand water-cooled printheads,

with 11 heads across the width to give

1,200dpi.

Although it handles offset papers as

standard, Ricoh will release an optional

Undercoater later this year that it says “may

enhance results on some coated and

uncoated offset stocks.” It isn’t needed for

inkjet coated stocks.

It shares ‘Swing & Shift’ sheet registra-

tion technology with Ricoh’s toner presses,

with accuracy comparable to an offset

press, the company claims. Paper is trans-

ferred onto the cylinder drum with grip-

pers, then held by vacuum during printing.

An alignment mark printed on each top

sheet is detected for front-to-back registra-

tion.

What does it do? Specifications The full sales release started on 1 April this

Process DoD piezo year. There’s an inline scanner for closed-loop

This is a B2-plus format sheetfed duplex inkjet quality control. Jet-outs can be detected

inkjet press, with CMYK aqueous inks. It Tim Carter, commercial print director at and compensated for during the run.

can handle offset coated, uncoated and Inks Aqueous, CMYK Ricoh UK Graphic Communications, says:

inkjet optimised papers, with Ricoh claim- “The Pro Z75 was developed to help com- Printhead cleaning is handled by an auto-

ing high quality for applications including Resolution mercial printers reach new levels of pro- mated web and blade system. Drying uses a

commercial printing, direct mail, colour 1,200x1,200dpi ductivity and image quality, with combination of IR, LED lamps and air

books and personalised packaging. It’s competitive operating costs. It is positioned knives.

intended to take over short-run offset work, Throughput to empower commercial printers to transi- This is a four-colour press but Carter says

while offering higher capacity but lower 4,500sph simplex tion from short-run offset to profitable the print engine has “space for additional

or 2,200sph duplex

operating costs than dry toner digital for up to 330gsm high-quality digital inkjet printing.” rows of printheads and therefore extra col-

presses. Although slower than offset weights So far there are no inline finishing ours are a future possibility. However, the

presses, there’s no downtime for plate options. However, Ricoh points out that it’s inks already offer a broad colour gamut”.

changes and makeready, and paper can be Max paper size compatible with standard finishing kit

changed on the fly. B2-plus developed for B2 litho presses. Covers-open photographs show room for

The Z75 name refers to the nominal (585x750mm) Ricoh’s other ‘Pro’ sheetfed digital colour two more rows.

750mm maximum sheet length (it will take presses, the Pro C7500 and Pro C9500, are The standard high-capacity stacker takes

banners longer than that). Paper weight range long-SRA3 formats that handle substrates about 7,200 sheets, with the optional sec-

115-400gsm from 40-470gsm, compared with the

uncoated, ond stacker allowing unloading without

When was it launched and what mar- 80-400gsm coated 60-400gsm of the Pro Z75. The Pro C7500 stopping. A tape inserter separates different

kets is it aimed at? also has a fifth colour station. jobs. A proofing tray on top can deliver

Pro Z75 was first announced in 2020. It Footprint 12.2x3.9m The B2-plus format of the Pro Z75 allows small, more urgent jobs.

was delayed by Covid, so it was late 2023 larger imposition schemes if needed, and The Fiery Controller and HyperRIP are

before there was a limited “controlled Weight 13,500kg increases throughput with the optional pal-

release” in Japan. It was demonstrated in let feeder and dual stacker. common with the Pro C7500 and C9500.

Europe as a big part of Ricoh’s Drupa stand The press’ large control touchscreen shows

a year ago, where in keeping with Ricoh’s How does it work? status, paper settings, remaining paper and

new animal naming scheme, it was called It’s a sheetfed inkjet press with inline ink, job queues and status, and the mainte-

Dragon and given dramatic wrap graphics. duplexing that handles sheets of B2-plus. nance schedule.

The inkjet print engine uses Ricoh’s own drop-on-demand water-cooled printheads.

www.printweekmena.com August 2025 PrintWeek MENA 29