FESPA Middle East 2026 concludes with strong industry engag…

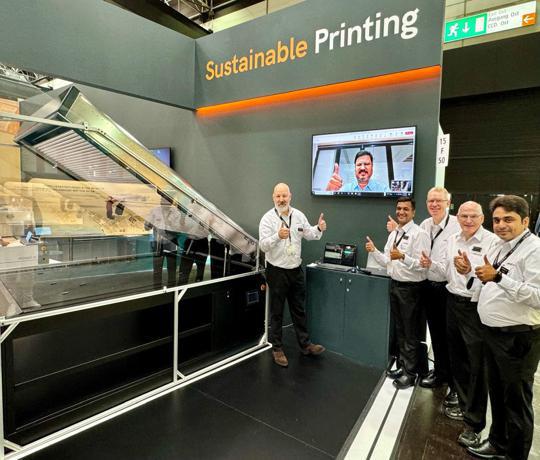

Canon Middle East is participating in FESPA Middle East from January 29 to 31, 2024, at the Dubai Exhibition Centre (Expo City). As the event's Gold Sponsor, Canon will be showcasing its industry-leading printing solutions, while demonstrating its commitment to driving innovation in the digital printing and signage industry.

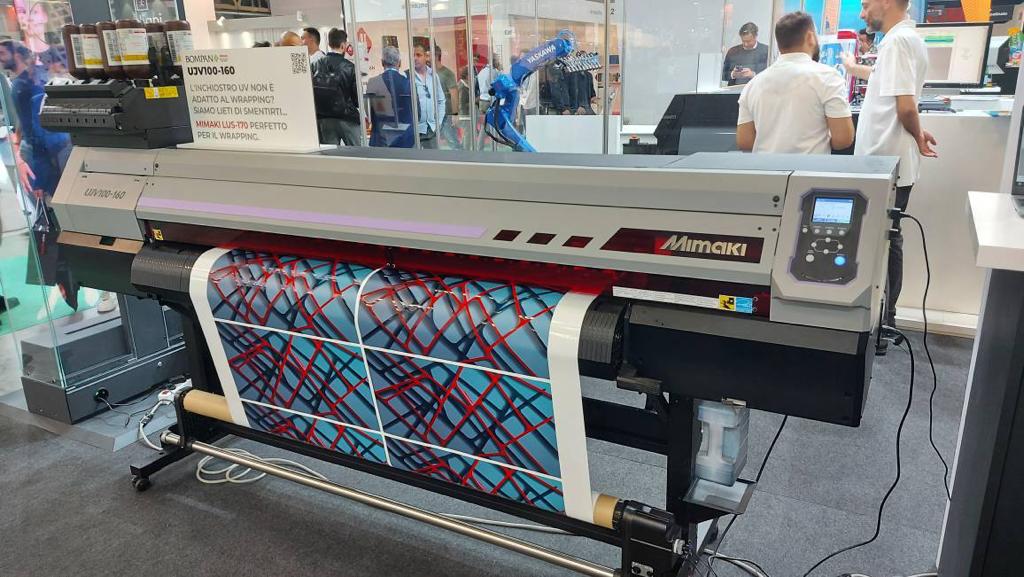

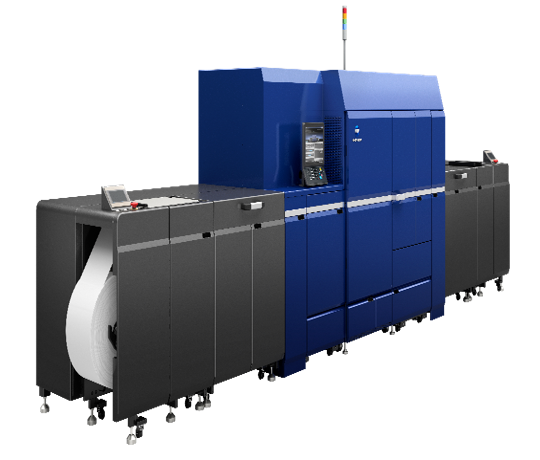

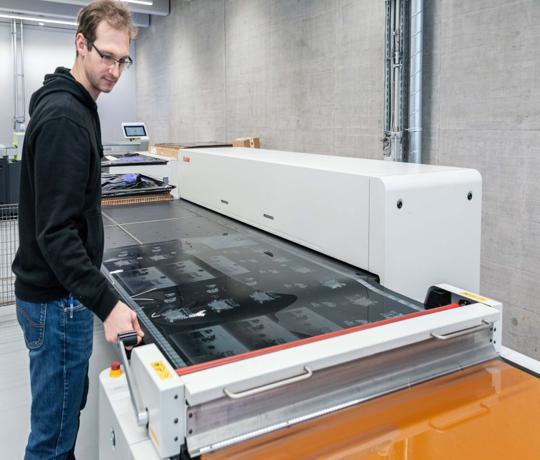

At the event, Canon will showcase its wide format graphics and packaging solutions, including three flagship products - the Colorado M Series, the Arizona 1360GT, and the ImagePROGRAF PRO 2600 – which will be debuted for the first time in the EMEA region, with a grand unveiling on the stand.

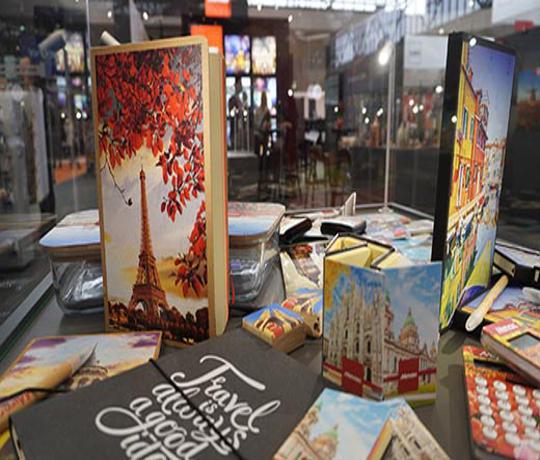

In addition to its own products, Canon will collaborate with partners to showcase finishing solutions and applications related to packaging. Visitors to the exhibition can experience instant personalized canvas production using Canon's products, packaged in boxes printed with the company's technology. Various print samples related to packaging will also be on display, highlighting the breath of applications which can be produced using Canon’s devices.

Shadi Bakhour, B2B Business Unit Director at Canon Middle East, stated: "I am thrilled to announce our participation as the Gold Sponsor at FESPA Middle East 2024. This event marks a significant milestone for us, being the first time FESPA is held in the region, and we are proud to play a leading role in bringing the latest innovations to the forefront. At our stand, we will showcase our cutting-edge printing solutions and emphasize our commitment to driving innovation in the digital printing and signage industry."

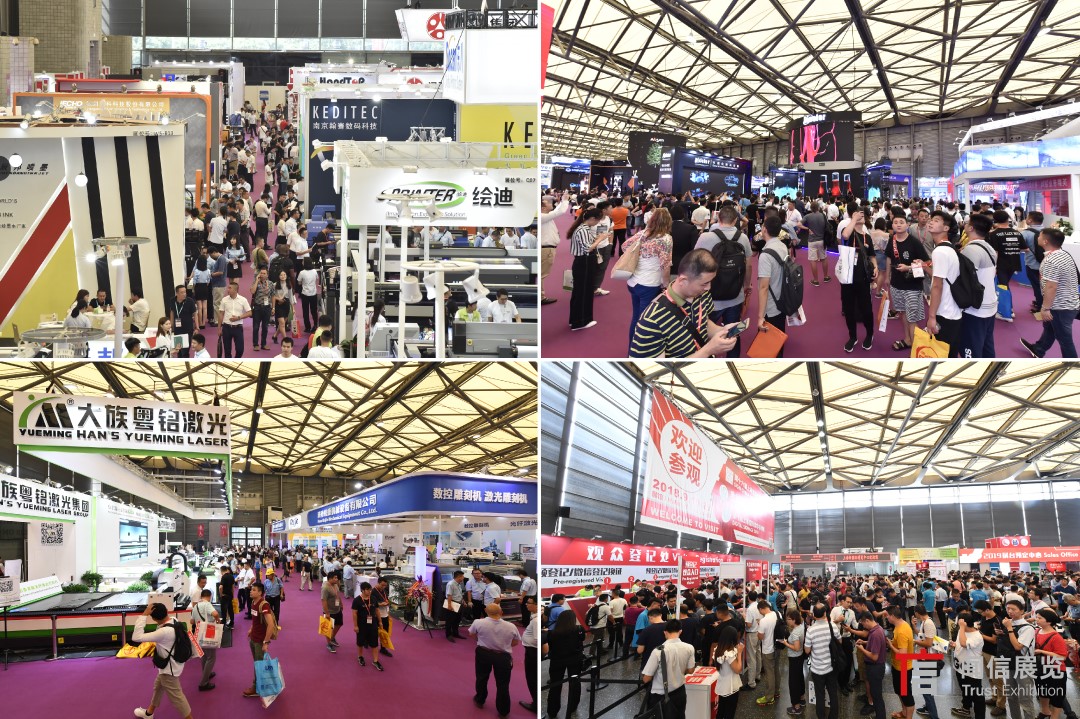

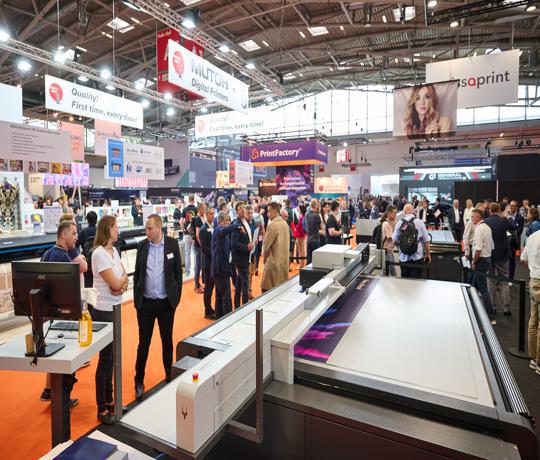

Held for the first time in the region, FESPA will unite the printing and signage industries, providing senior professionals from across the region with an opportunity to discover new technologies, applications, and consumables in digital printing and signage solutions from leading brands. The show will also allow visitors the chance to discover the latest trends, network with industry peers and make valuable business connections.

Mathew Faulkner, EMEA Marketing & Innovation Director, Wide Format Printing Group, Canon Europe comments, “Over the last few years, we’ve seen the use of wide format applications increasing, especially in areas such as posters, banners and signage as retailers work hard to drive footfall and create impactful communications and wayfinding. With changing consumer preferences, we’re also seeing application use increasing in more expert markets such as interior décor - and packaging, where digital print on demand is enabling personalised packaging to be used as another valuable communications touchpoint.

Our stand at FESPA Middle East reflects this with technology displays, a broad range of unique applications and inspirational ideas to help printers go the extra mile and deliver profitable growth. We’ll be showcasing our market leading wide format portfolio – which includes flat bed, roll to roll and workflow solutions - as well as bringing to life a range of applications using vivid colours, special effects, and unique designs. We’re excited to support the inaugural FESPA Middle East and have the opportunity to connect with this important market segment.”

Visit Canon's booth in Hall 2, stand D20, to witness groundbreaking technology and explore sustainable solutions for your printing needs.

_wrZSl8o_RRCJFlQ.gif)

.jpg)

.jpeg)

.jpg)

.png)

.jpg)

_hw13rw8.jpeg)

Recent Comments