BOBST and IPS bring innovation and insights to Egypt with C…

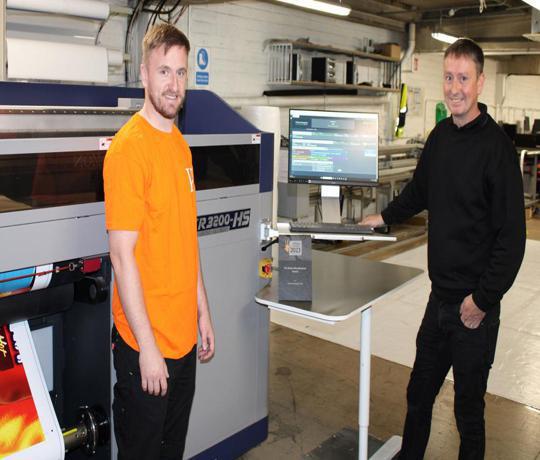

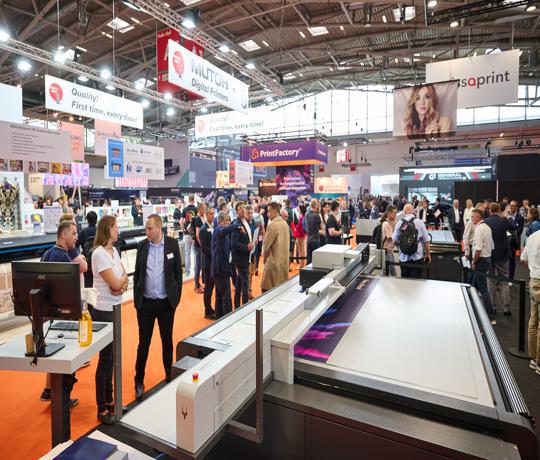

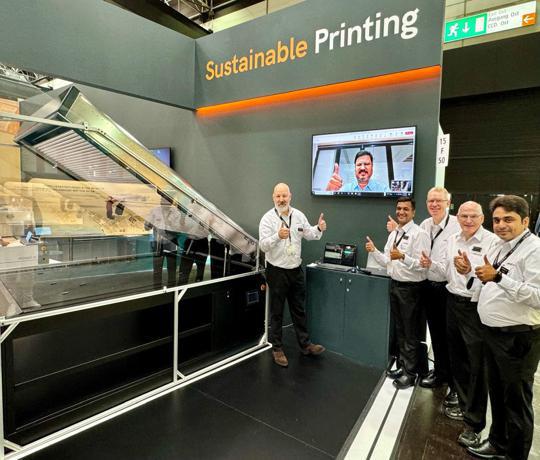

BOBST, together with its agent for Egypt, IPS, gathered the Egyptian packaging industry in Cairo on 3rd February 2026 for a full-day event dedicated to the latest technological advances across labels, flexible packaging, folding cartons, and corrugated packaging.

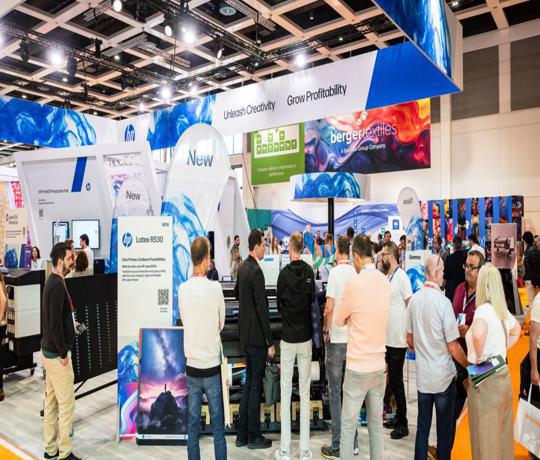

Hosted at Hilton Heliopolis Cairo, the event welcomed converters, brand owners, and industry partners for a comprehensive program of presentations, demonstrations, and networking designed to highlight the opportunities shaping the future of packaging production. Alongside BOBST’s panel of experts, partner companies Reifenhäuser, Baumer HHS, ACE, Rossini, Eterna, DEC Group, and GEW contributed to the day’s discussions, each sharing valuable insights into their respective fields of excellence.

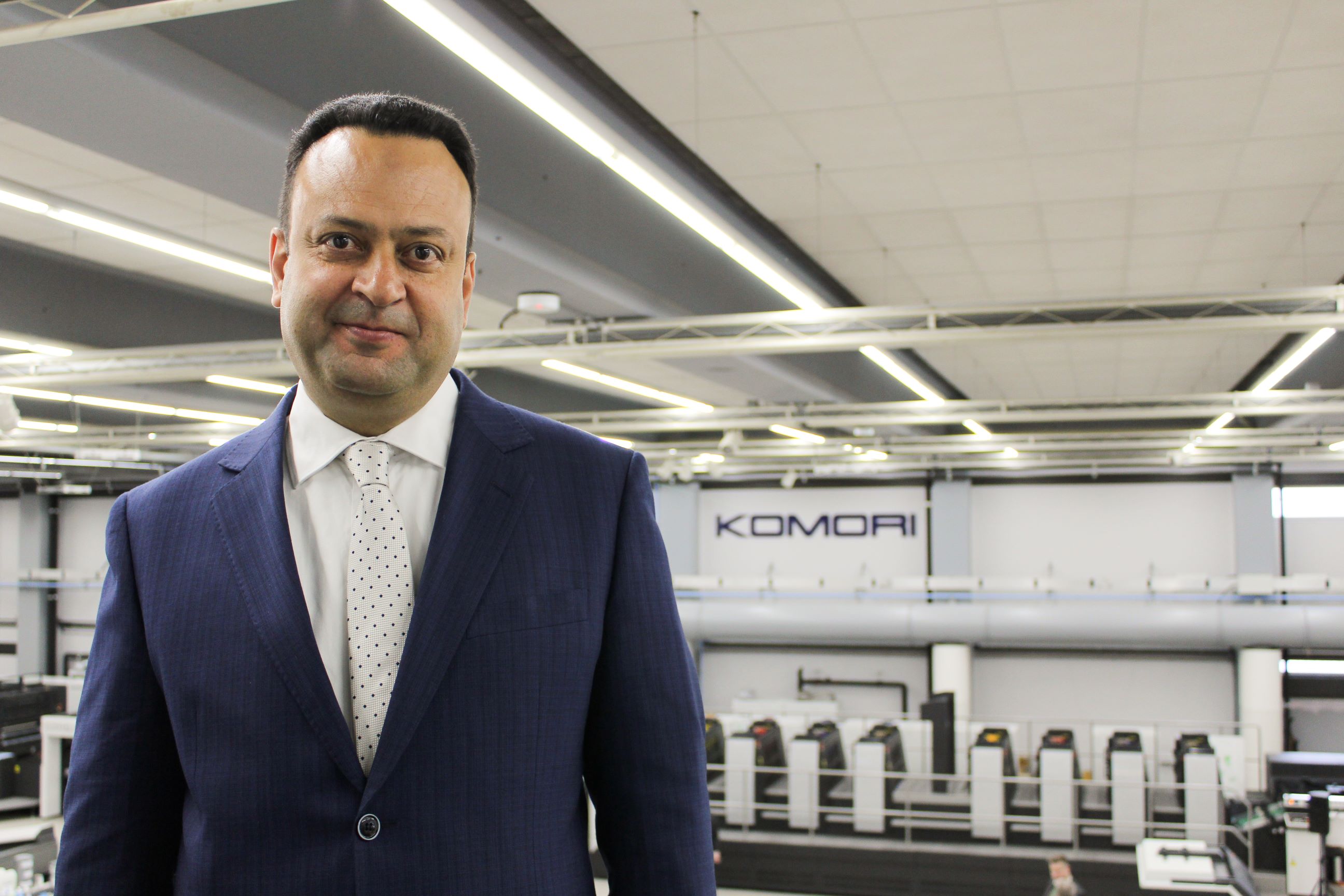

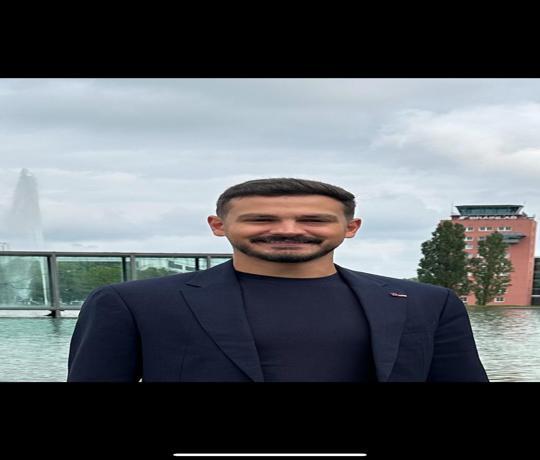

“Egypt is becoming an increasingly important hub for packaging innovation in the Middle East and North Africa,” said Khaled Joundi, Regional Business Director for the Middle East, Egypt and Turkey region. “Our Cairo roadshow offered participants a platform to engage with leading specialists, discover cutting-edge technologies, and understand how BOBST and its partners are driving progress in productivity, automation, and sustainability. The feedback from attendees has been extremely positive, underlining the importance of such collaborative industry events.”

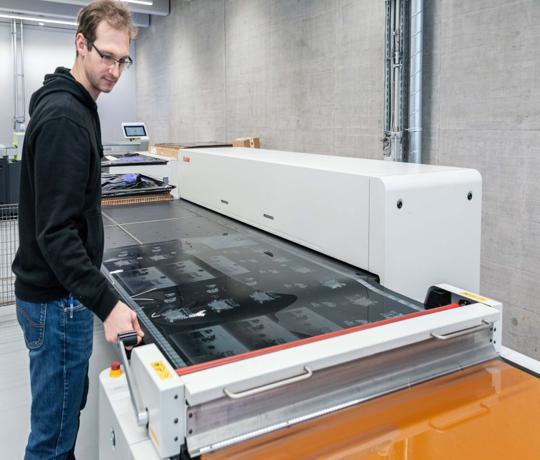

The program covered all major packaging segments. For folding carton and corrugated manufacturers, BOBST presented the latest developments around the NOVA FFG flexo folder-gluer, as well as the ETERNA range of converting solutions, both offering cost-effective, high-performance options to strengthen competitiveness.

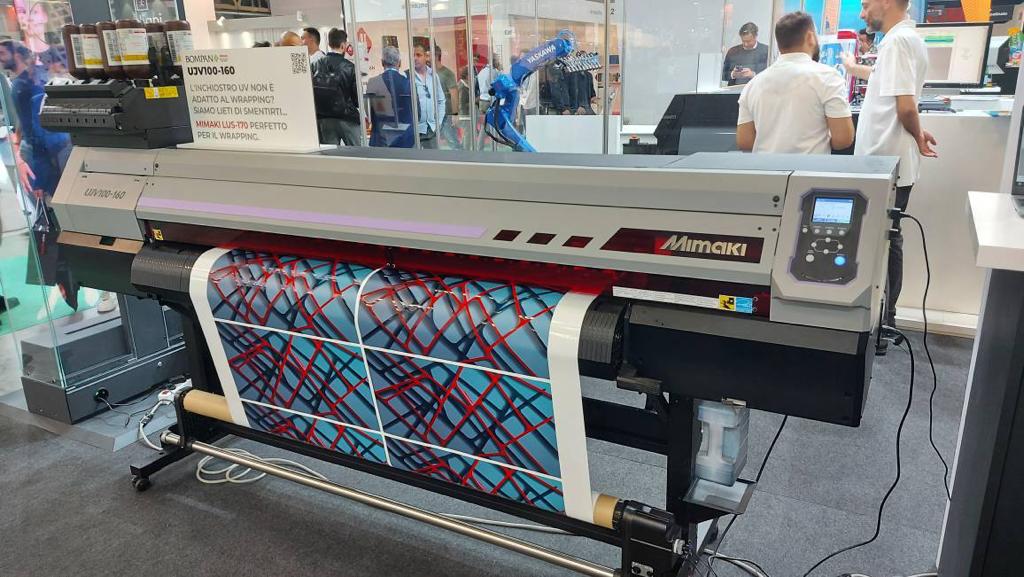

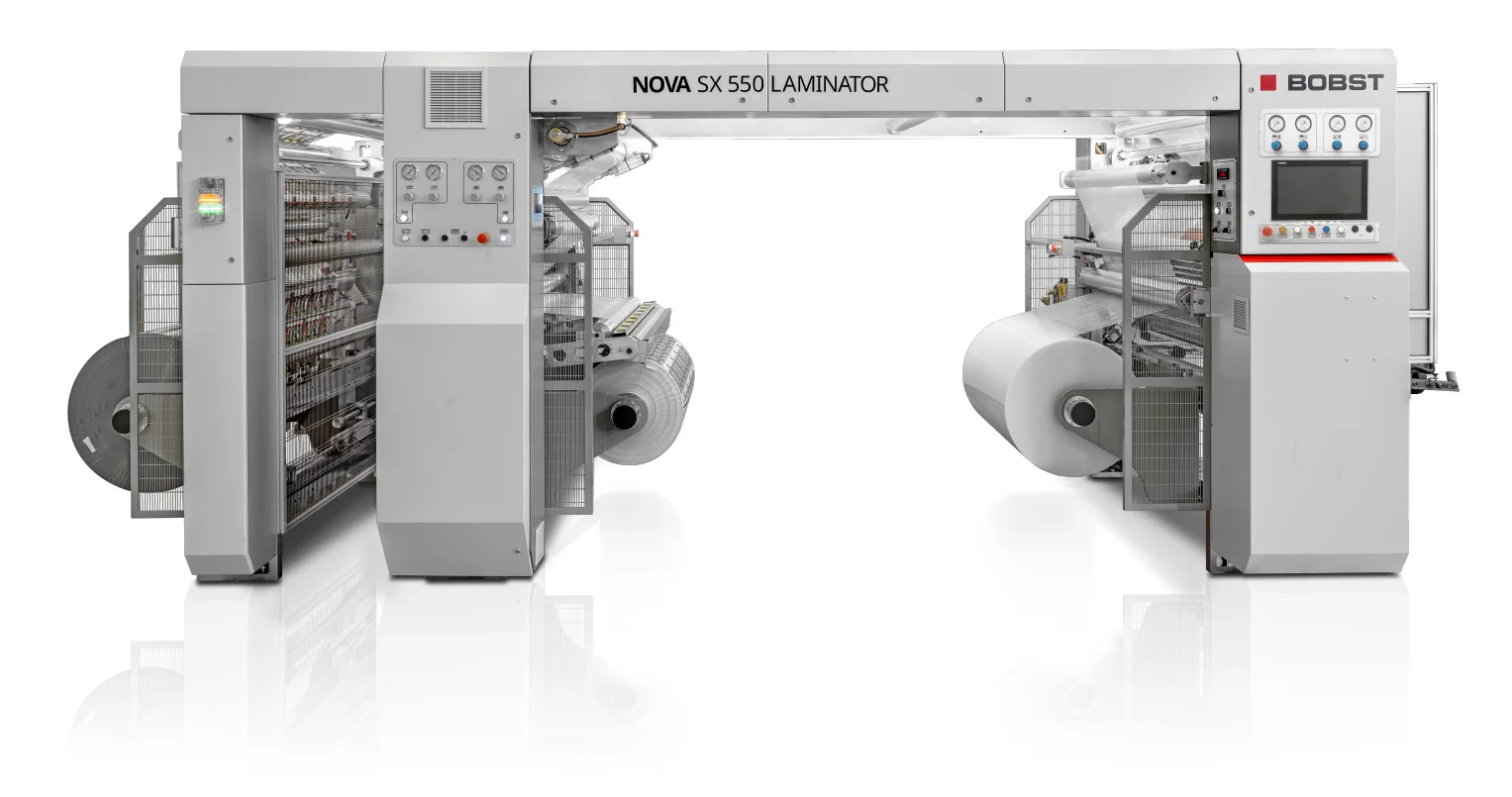

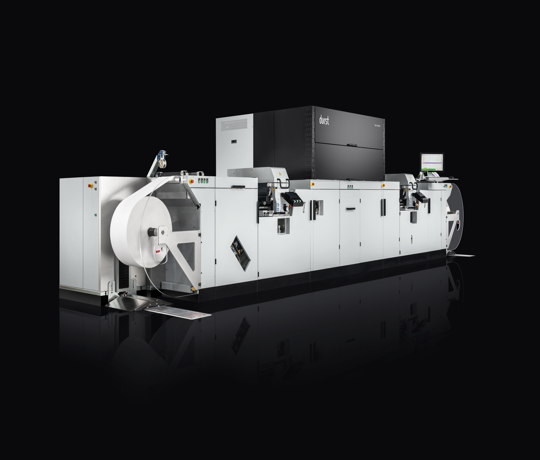

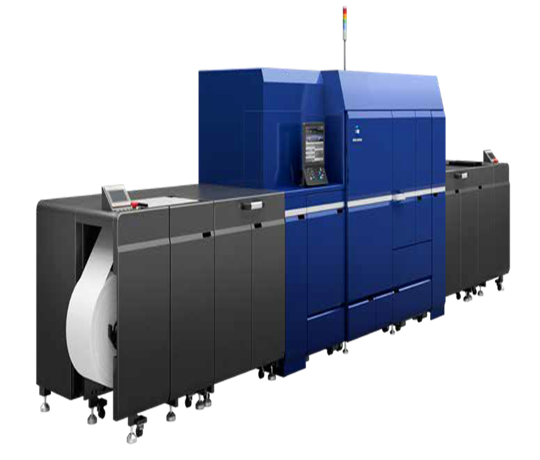

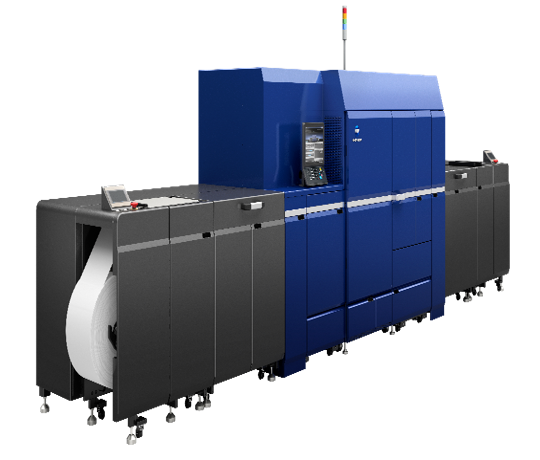

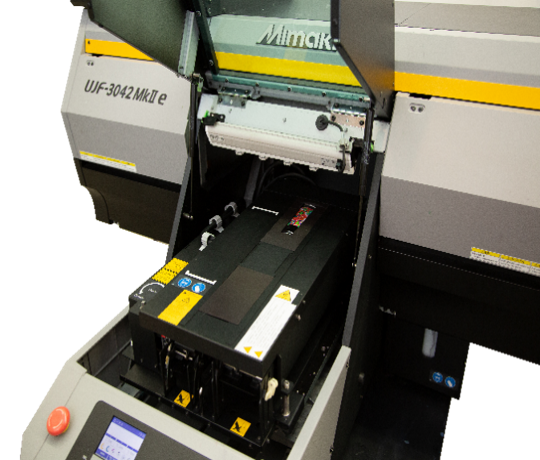

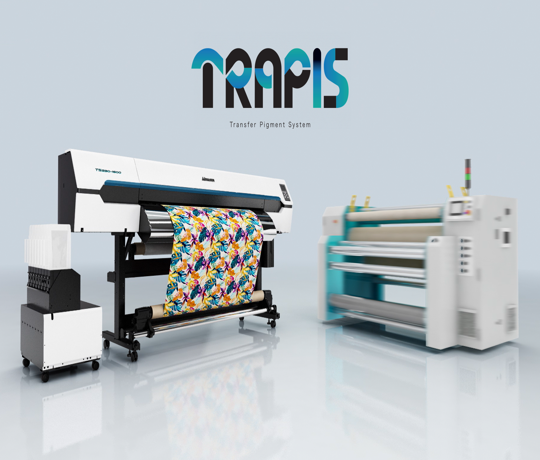

For flexible packaging converters, the VISION CI flexo press and the NOVALAM 800 laminator demonstrated a powerful combination of efficiency, modularity, and sustainable production capabilities. Meanwhile, the VISION M1, MASTER M5, and MASTER M6 inline flexo presses attracted strong interest from label converters thanks to their high level of automation, versatility, and end-to-end digitalization.

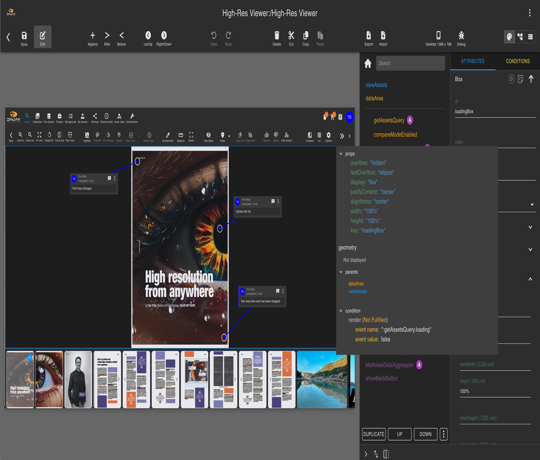

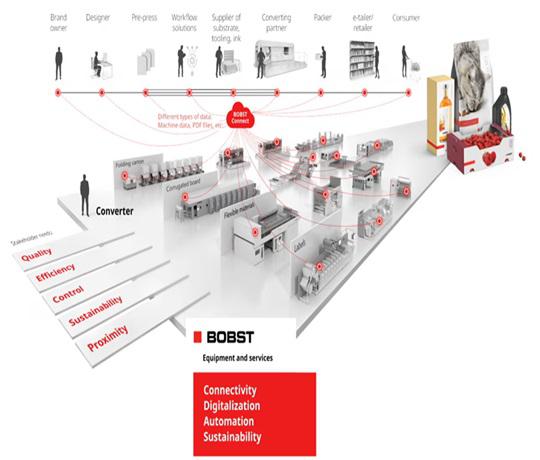

The agenda also included discussions on BOBST Connect, the cloud-based digital platform that enhances visibility and performance across production workflows. Experts shared updates on gravure digitalization, coating and metallization innovations, tooling performance, equipment financing options, and BOBST’s comprehensive support and services offering.

Partner companies contributed to the dialogue with technology updates, while Eterna shared cost-efficient pathways for converting and packaging production.

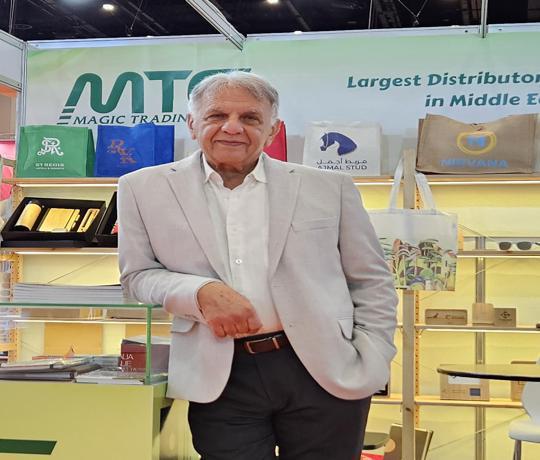

“The event reflected a very positive level of engagement across the industry,” said Dr. Sameh Sidhom, CEO of IPS. “Our partnership with BOBST is built on trust and a shared commitment to bringing innovative, high-performance solutions to converters across Egypt.”

_wrZSl8o_RRCJFlQ.gif)

.jpg)

.jpeg)

.jpg)

.png)

.jpg)

_hw13rw8.jpeg)

.jpg)

Recent Comments