FESPA Middle East 2026 concludes with strong industry engag…

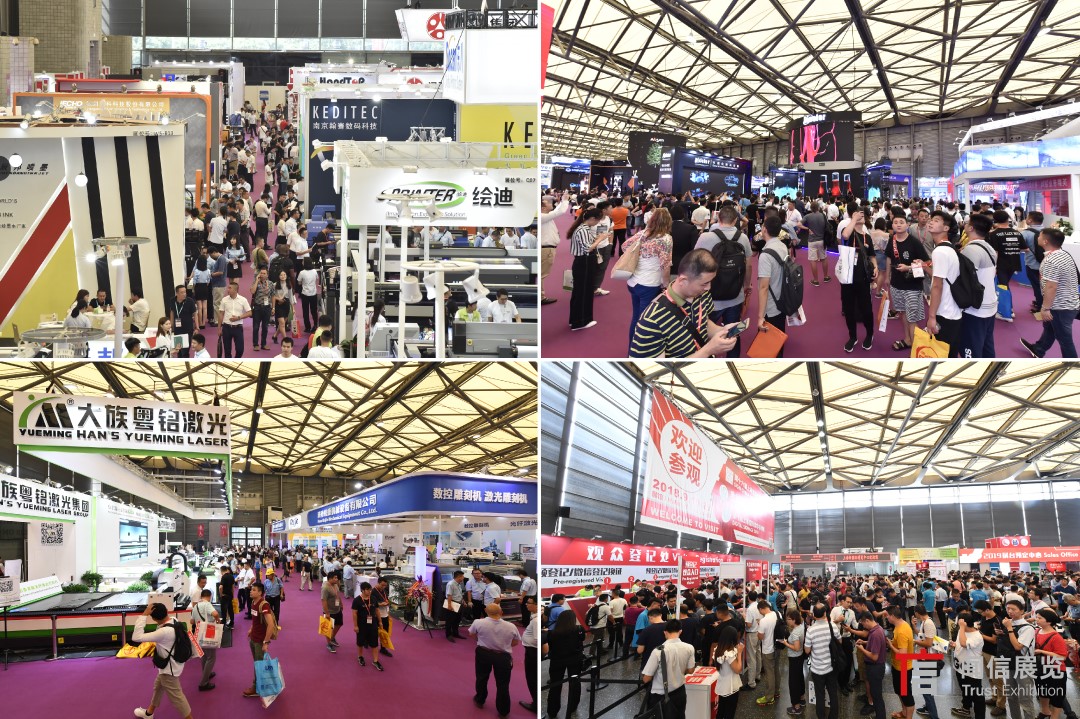

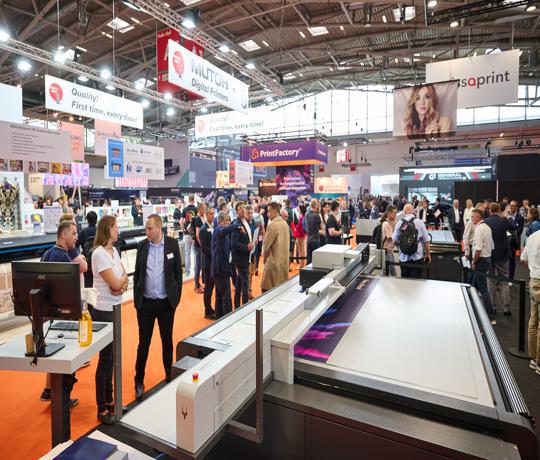

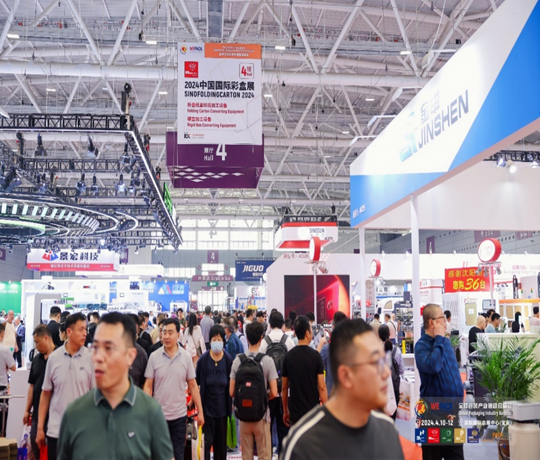

FESPA Middle East 2026 concluded at the Dubai Exhibition Centre on 15 January 2026, marking three days of high-level engagement, knowledge-sharing and live competition across the speciality print and signage sector. From the opening day (13 January 2026), the event set a strong pace, with busy aisles and a highly engaged audience exploring the latest product innovations. Thought-leading conference sessions addressed key themes shaping the industry, including AI, automation, sustainability and wider industry transformation. Live World Wrap Masters competition action tested elite wrappers on skill, speed and precision, while Wrap Demos delivered hands-on techniques, practical tips and real-world application insight that resonated strongly with visitors.

Building on this momentum, the conference programme continued to deepen discussions around the strategies driving modern print businesses. Sessions explored storytelling and design-led experiences, print-on-demand models, sustainability as a growth driver, and the role of technology and AI in scaling operations. Panel discussions brought diverse perspectives together, examining how businesses are adapting to evolving customer expectations, expanding into new markets and building workflows that support speed, flexibility and long-term growth.

The final day brought standout moments across the conference stage and live feature areas, culminating in the crowning of the World Wrap Masters Middle East Champion. The closing sessions reinforced the industry’s focus on future-ready print, automation and personalisation, while the final wrap demonstrations highlighted refinement, finishing excellence and performance under pressure.

As FESPA Middle East 2026 came to a close, the takeaway was clear: the conversations sparked on the show floor will continue well beyond the event itself. With strong participation from speakers, partners, exhibitors, competitors and visitors, the event once again demonstrated its role as a vital platform for connection, learning and progress within the Middle East’s speciality print community.

_wrZSl8o_RRCJFlQ.gif)

.jpg)

.jpeg)

.jpg)

.png)

.jpg)

_hw13rw8.jpeg)

Recent Comments