Tetra Pak maintains position on CDP leadership band for for…

Registrations are officially open to attend Gulf Print & Pack, the leading print and packaging technology exhibition in the Middle East and North Africa regions. Running from 31 March to 2 April 2026 at the Dubai World Trade Centre, the show will celebrate its 15th milestone edition with an unmatched gathering for printers, print service providers (PSPs), and brand owners.

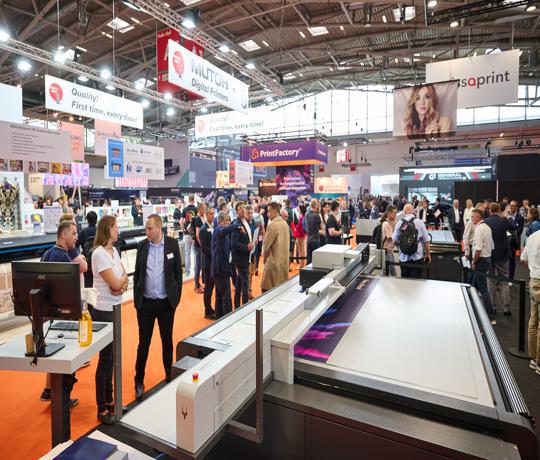

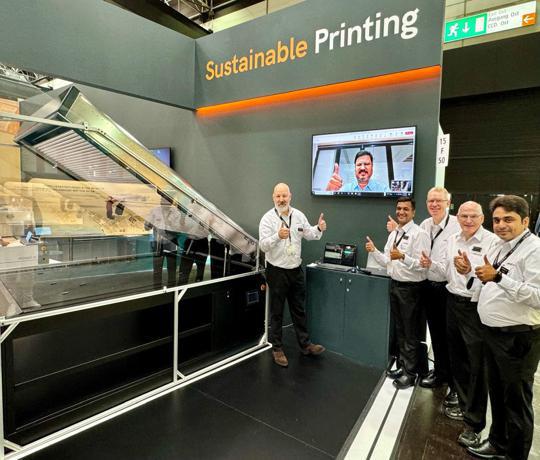

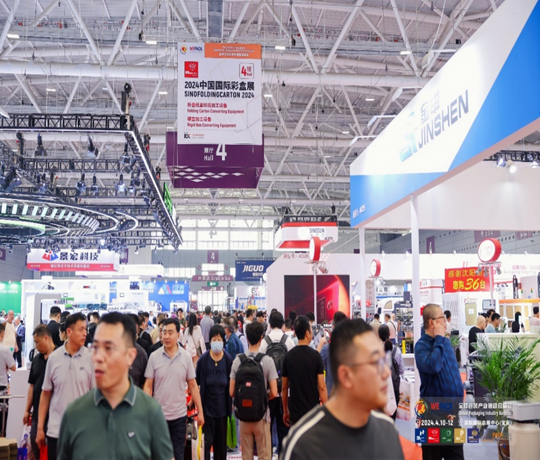

Gulf Print & Pack has established itself as a magnet attracting regional buyers by showcasing new technologies and innovation across machinery, materials and software, and a hub showcasing the power of print and packaging in the Middle East. The consistent growth and content quality focusing on innovation attract business leaders seeking to unlock opportunities and fuel sustainable growth.

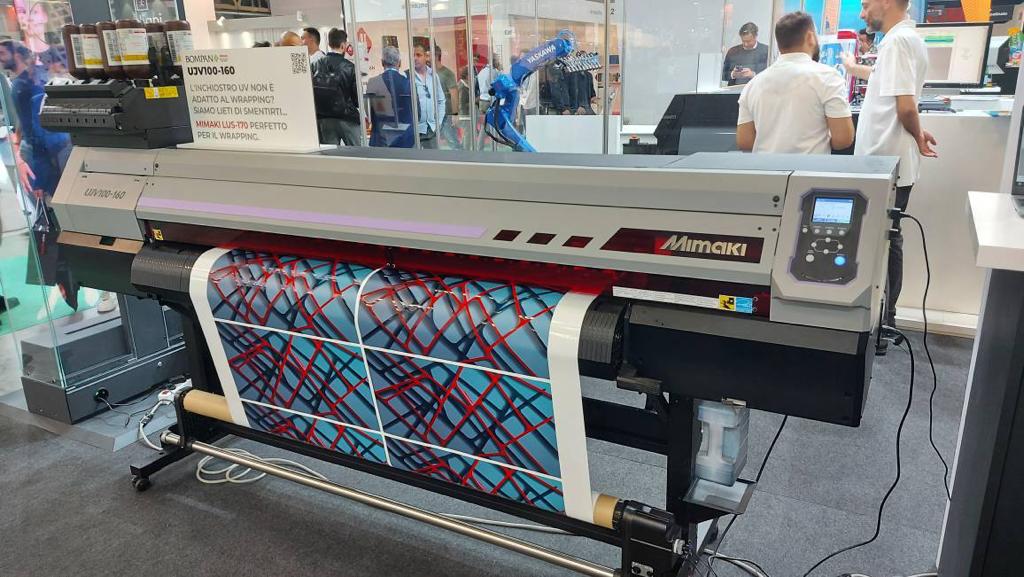

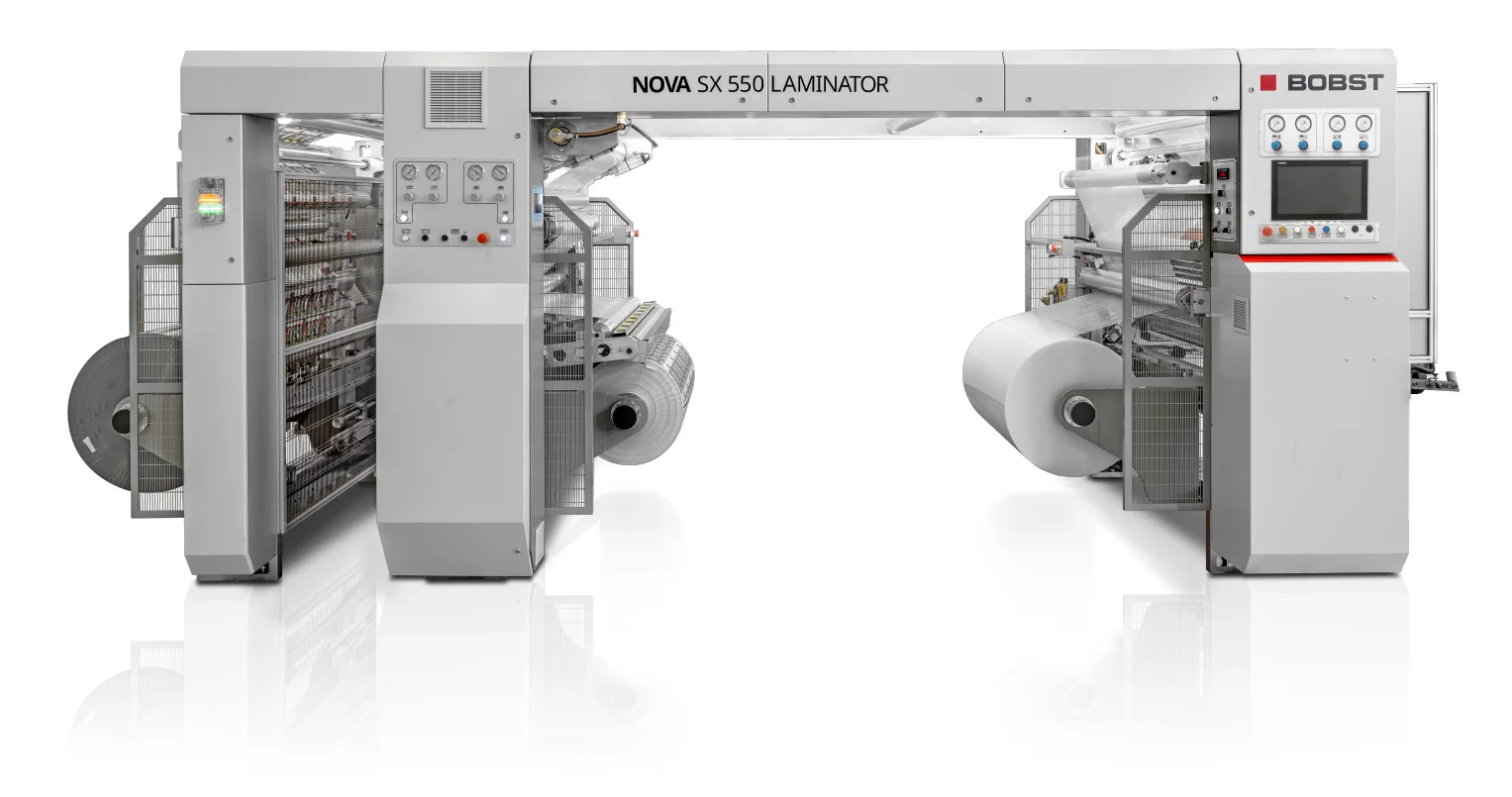

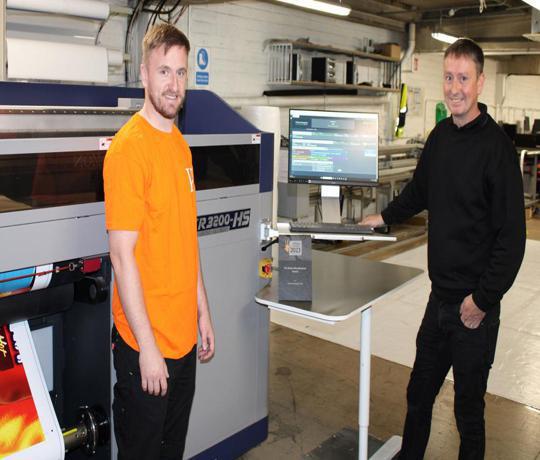

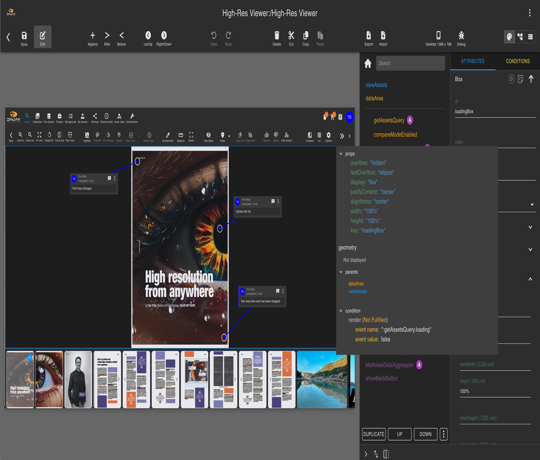

Barry Killengrey, Event Director at Gulf Print & Pack, shared some of the focus areas in the upcoming edition: “Gulf Print & Pack 2026 will spotlight how technology and digitalization are transforming the print and packaging industry. With more machines running live on the show floor than ever before the exhibition will give visitors an experience of how innovation is driving new opportunities for business growth.”

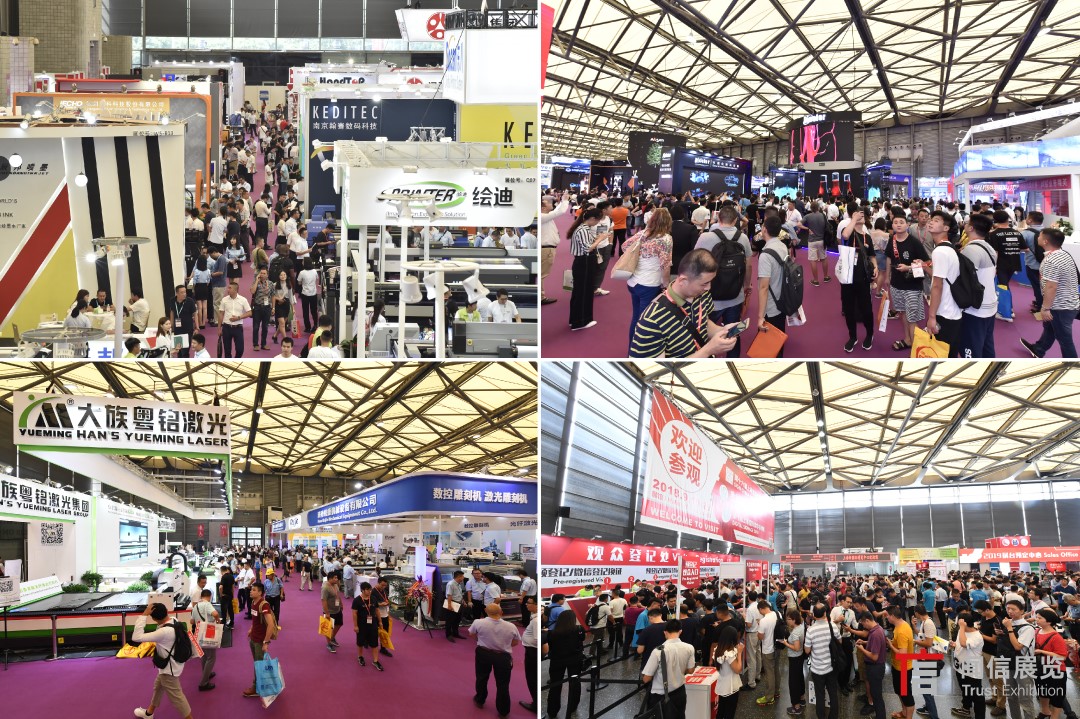

Focusing on the regions’ unique growth, the show has, in the past edition, attracted over 8,000 print and packaging professionals from 100+ countries. In 2026, Gulf Print & Pack is set to grow even further, expecting 300+ manufacturers and suppliers, an increase from 250 in 2024, occupying an increased exhibition area.

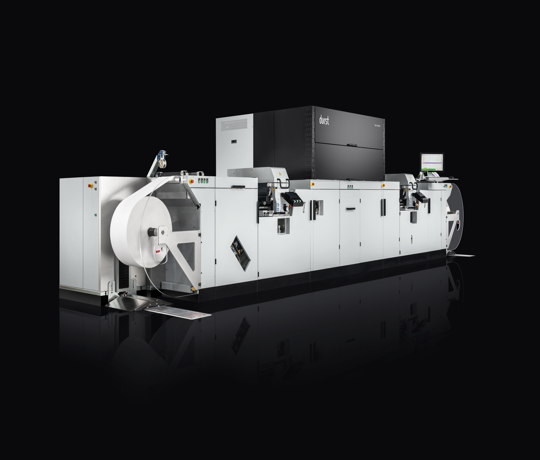

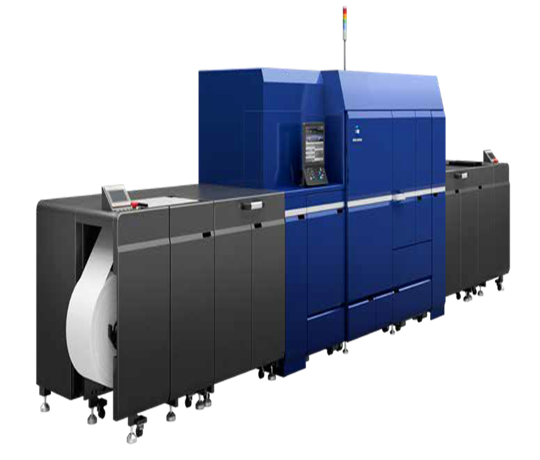

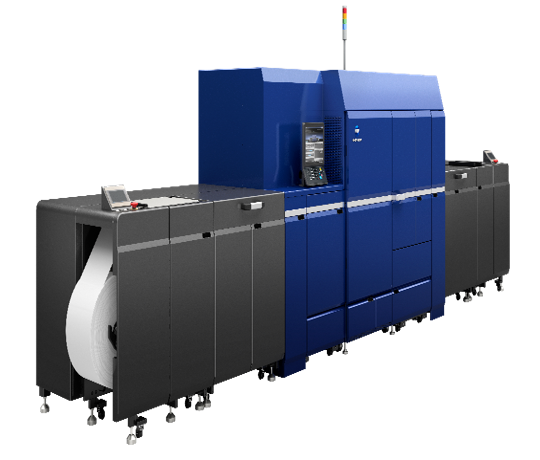

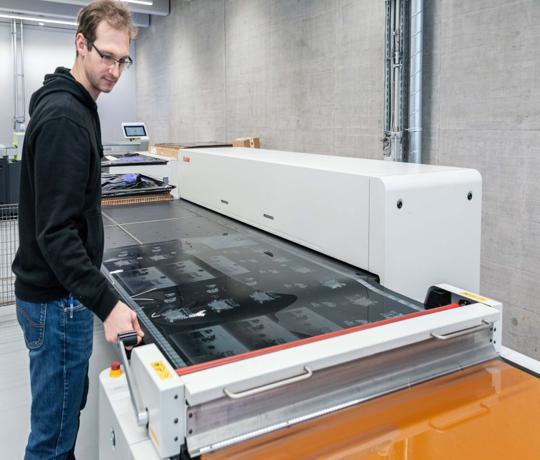

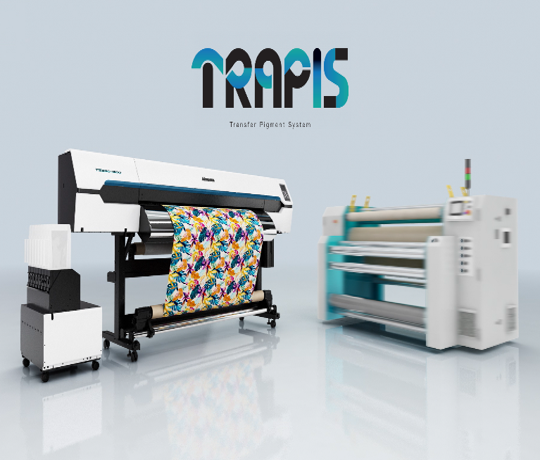

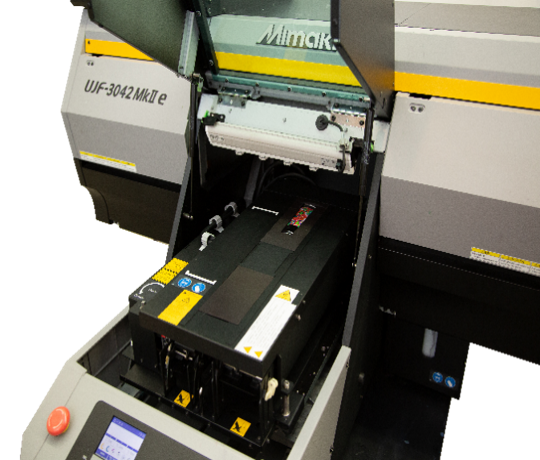

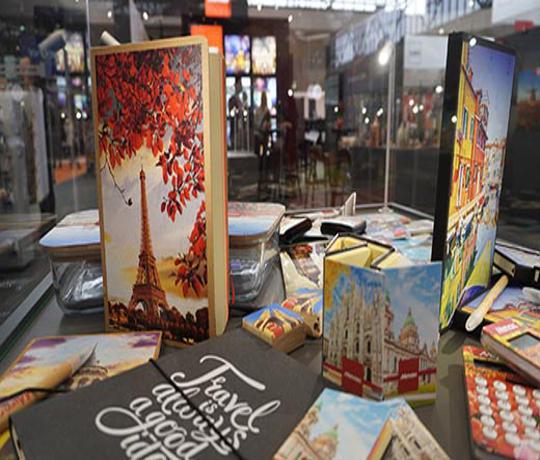

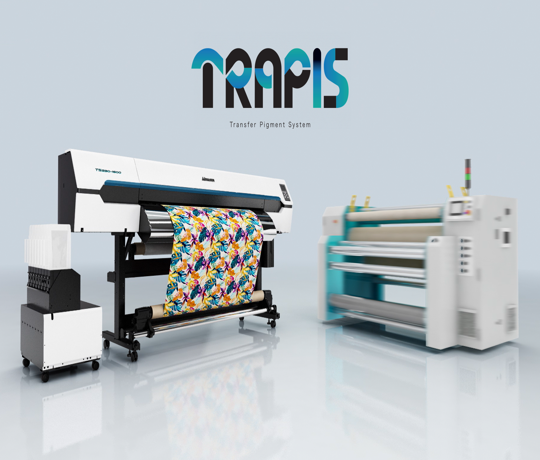

For visitors, Gulf Print & Pack offers the unique opportunity to see the full production journey in one place, from pre-press through to post-press; and discover the latest innovation in digital, flexo and hybrid printing, plus advances in finishing, embellishment, and materials. Live demonstrations on the show floor showcase a range live machinery in action covering books, photobooks, direct mail, transactional printing, digital textiles, wallpaper, labels, and packaging.

Gulf Print & Pack takes place from 31 March to 2 April 2026 at the Dubai World Trade Centre and is free to attend for industry peers.

Register here: https://www.gulfprintpack.com/ - hyperlink to - https://www.gulfprintpack.com/?utm_source=partner&utm_medium=referral&utm_campaign=eme26gpp-zg-visprom-partner-print-week-mena-press-release-one-17-dec-25&utm_content=press-release

_wrZSl8o_RRCJFlQ.gif)

.jpg)

.jpeg)

.jpg)

.png)

.jpg)

_hw13rw8.jpeg)

.jpg)

Recent Comments