Customer-centric development of BOBST’s EXPERTFOLD corrugat…

The modularity of BOBST folder-gluers is rooted in the knowledge that not all customers have the same production needs. Based on their activity within specific market segments, customer requirements and plant size, converters aim to invest in solutions that match their manufacturing standards.

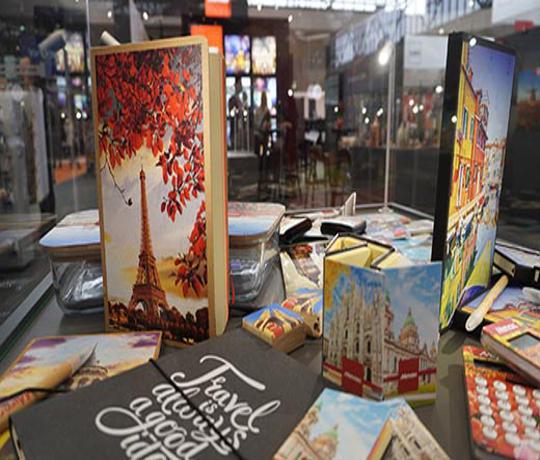

Modern converting for added-value boxes

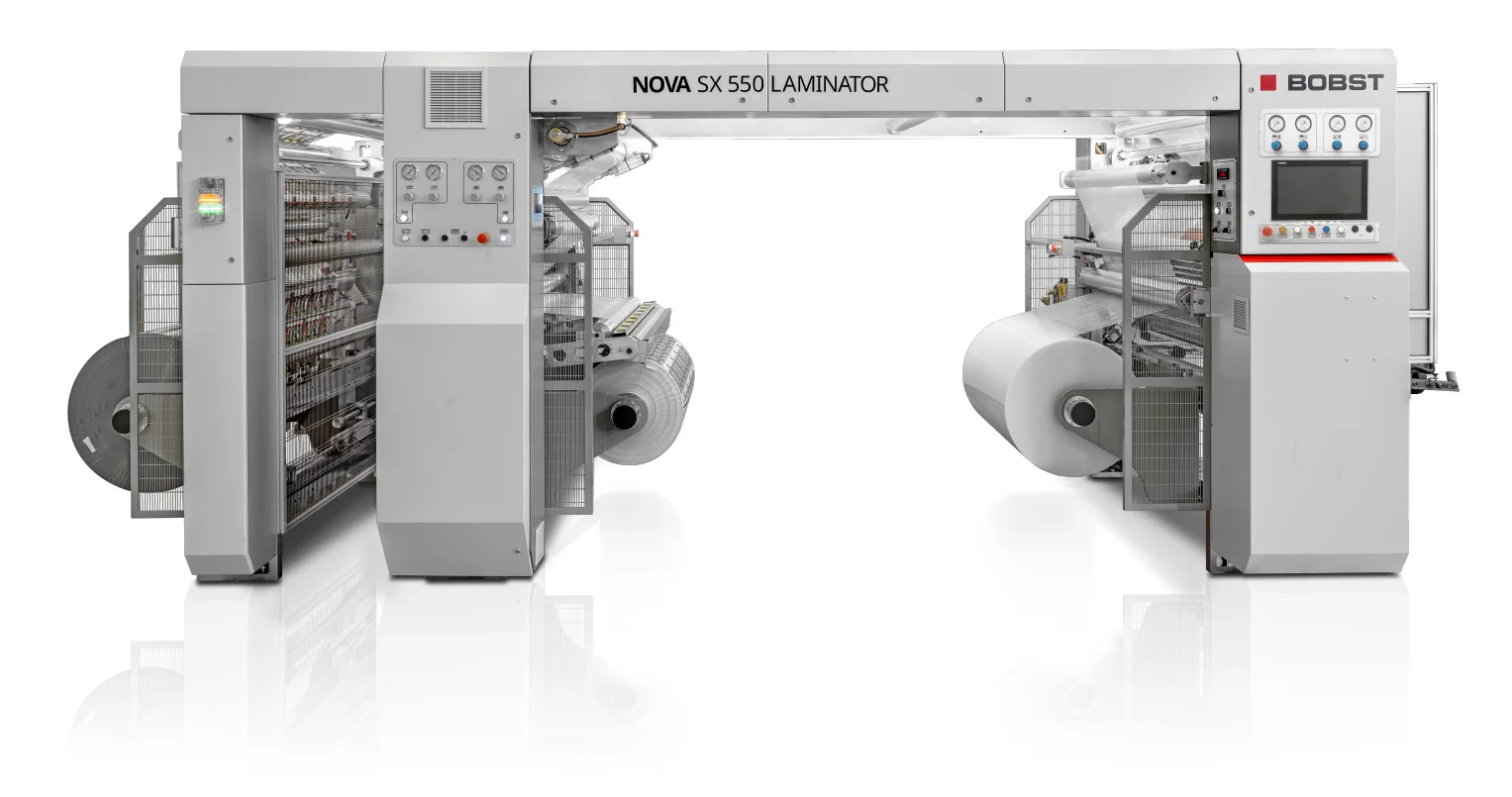

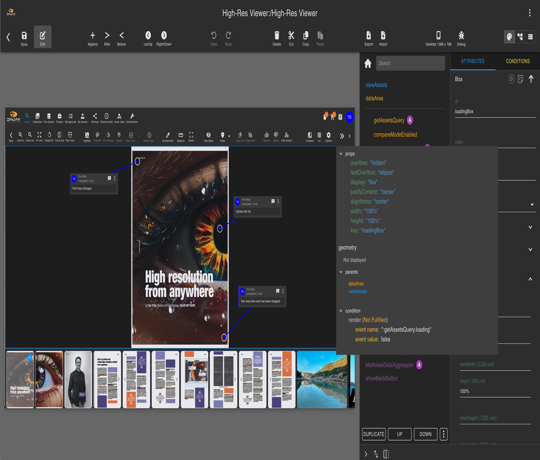

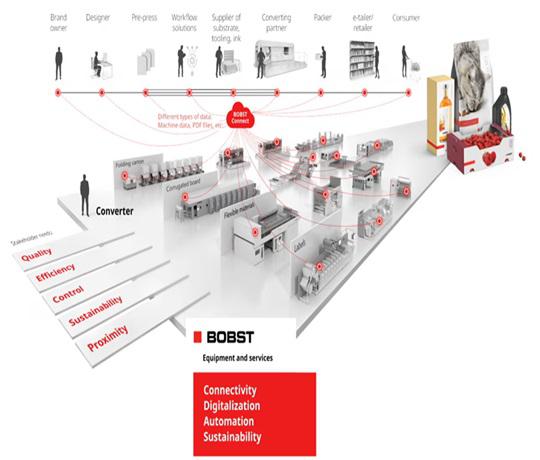

Designed to ensure careful and precise folding-gluing of corrugated board and delicate litho-laminated packaging, the EXPERTFOLD 145/165 is equipped with a range of features for smooth transport, exact folding and long-lasting gluing. The machine is equipped with HMI (Human Machine Interface) SPHERE, which allows data exchange with the back office through the BOBST Connect platform. Job details can now be prepared remotely, and production data is available through the platform. This provides converters with access to manufacturing reports and equipment data across production sites, enabling them to plan shifts effectively and monitor production progress and outcomes.

The combination of the remote digital setup with Matic features – including the new automated blank aligner – further streamlines, accelerates and simplifies the setup processes. Increased data and setup precision and reduced workload for operators are additional benefits of the latest changes implemented on the EXPERTFOLD.

Additional machine widths and configurations

A few years ago, the introduction of the special e-commerce configuration of the EXPERTFOLD 165, including a POLYVACUUM and GYROBOX module for the inline application of self-adhesive tapes and opening stripes, has been an important step in specializing this all-rounder for a particular market segment. Today, two new machine widths and configurations expand the options available to converters seeking high-tech folder-gluer dedicated to particular production requirements.

For smaller micro-flute boxes, EXPERTFOLD 106 offers a reduced width which allows to save precious production floor space by keeping the machine footprint at a minimum. At the same time, the machine contains all the technologies of its bigger version, preserving delicate packaging surfaces for first-rate quality converting of value-added boxes.

The new EXPERTFOLD 215, on the other hand, is dedicated for folding-gluing large blanks up to 2,300 mm width. Equipped with an extended feeder section and a 6,000 mm folding and a 6,600 mm delivery section, this extremely robust machine does not compromise on folding quality. To reduce the machine length, it is also available in a configuration without pre-breaker. However, it can also be equipped with POLYVACUUM and GYROBOX XL, to produce complex boxes in one single run.

These recent innovations and new machine widths are designed to offer converters even more possibilities to find the folder-gluer that suits their needs. It is also a way for BOBST to adapt its corrugated board folder-gluer portfolio to the trend towards high-end micro-flute and big-size e-commerce boxes.

_wrZSl8o_RRCJFlQ.gif)

.jpg)

.jpeg)

.jpg)

.png)

.jpg)

_hw13rw8.jpeg)

Recent Comments