BOBST presents insights and innovation for sustainable pack…

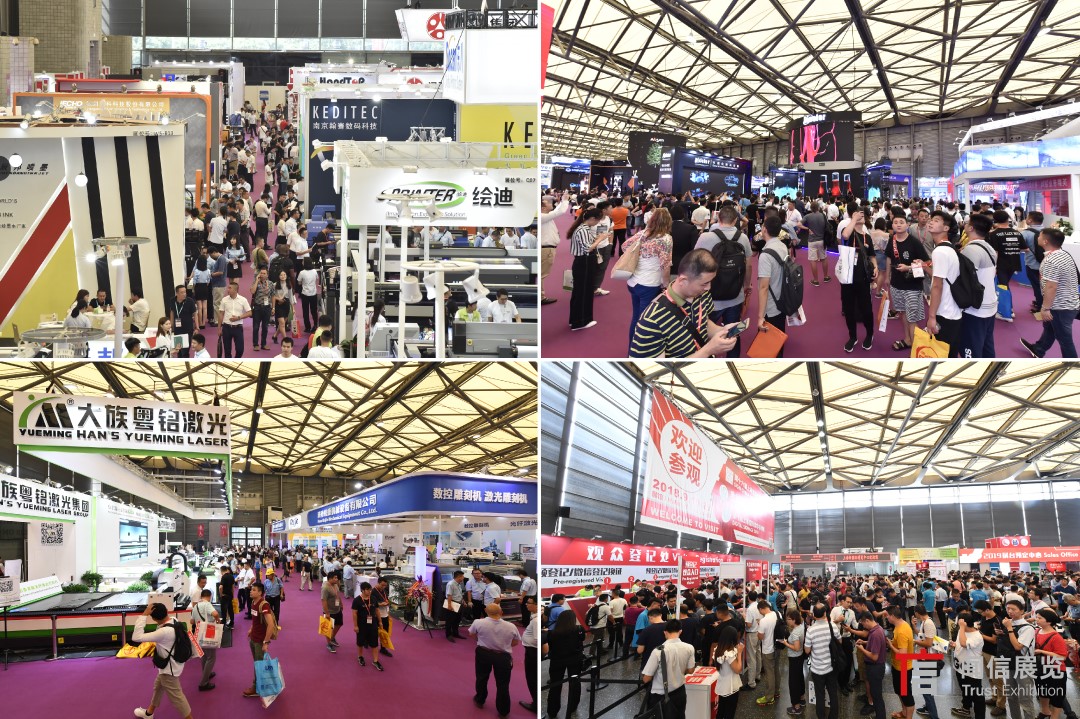

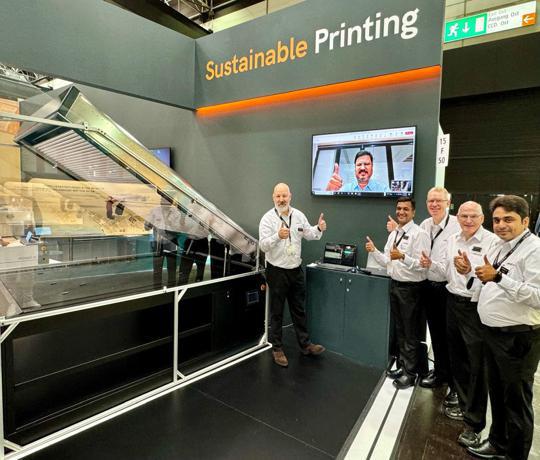

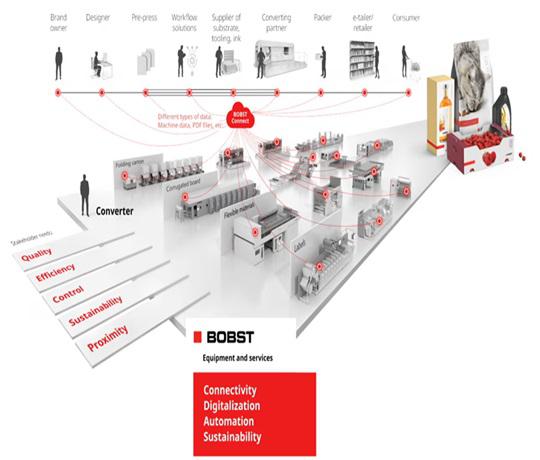

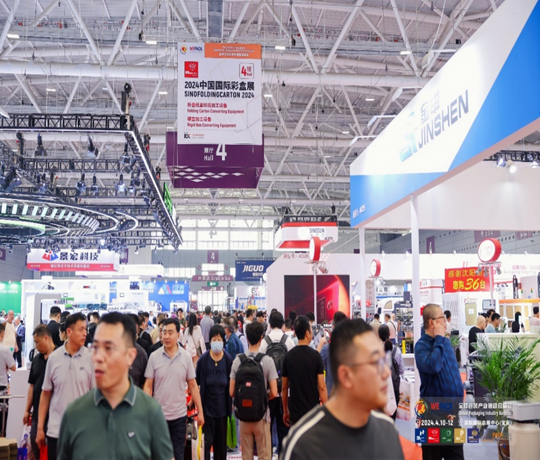

BOBST brought the packaging community together in Sousse in early December for a two-day event designed to introduce the latest innovations and sustainability solutions across labels, flexible packaging, folding cartons, and corrugated packaging.

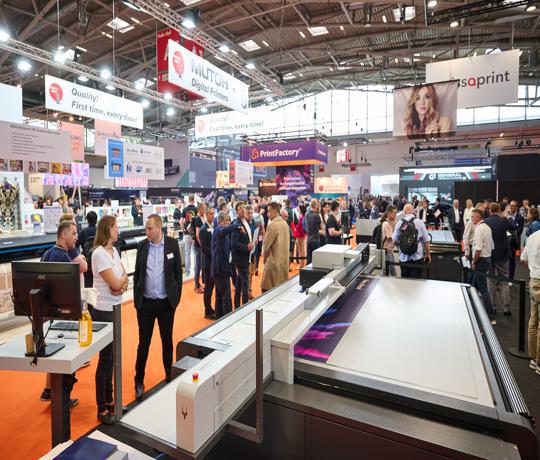

Held on 3 and 4 December 2025, BOBST welcomed more than 150 attendees to the Sousse Pearl Marriott Resort & Spa Hotel for a packed program of presentations and networking opportunities. The first day of the roadshow was dedicated to the folding carton and corrugated packaging sectors, while the second catered to label and flexible packaging converters. As well as a broad contingent of BOBST expert speakers, partner companies Baumer HHS, Esko, Kurz, Packitoo, Reifenhäuser, and Rossini joined the agenda, covering the key topics affecting the industry today.

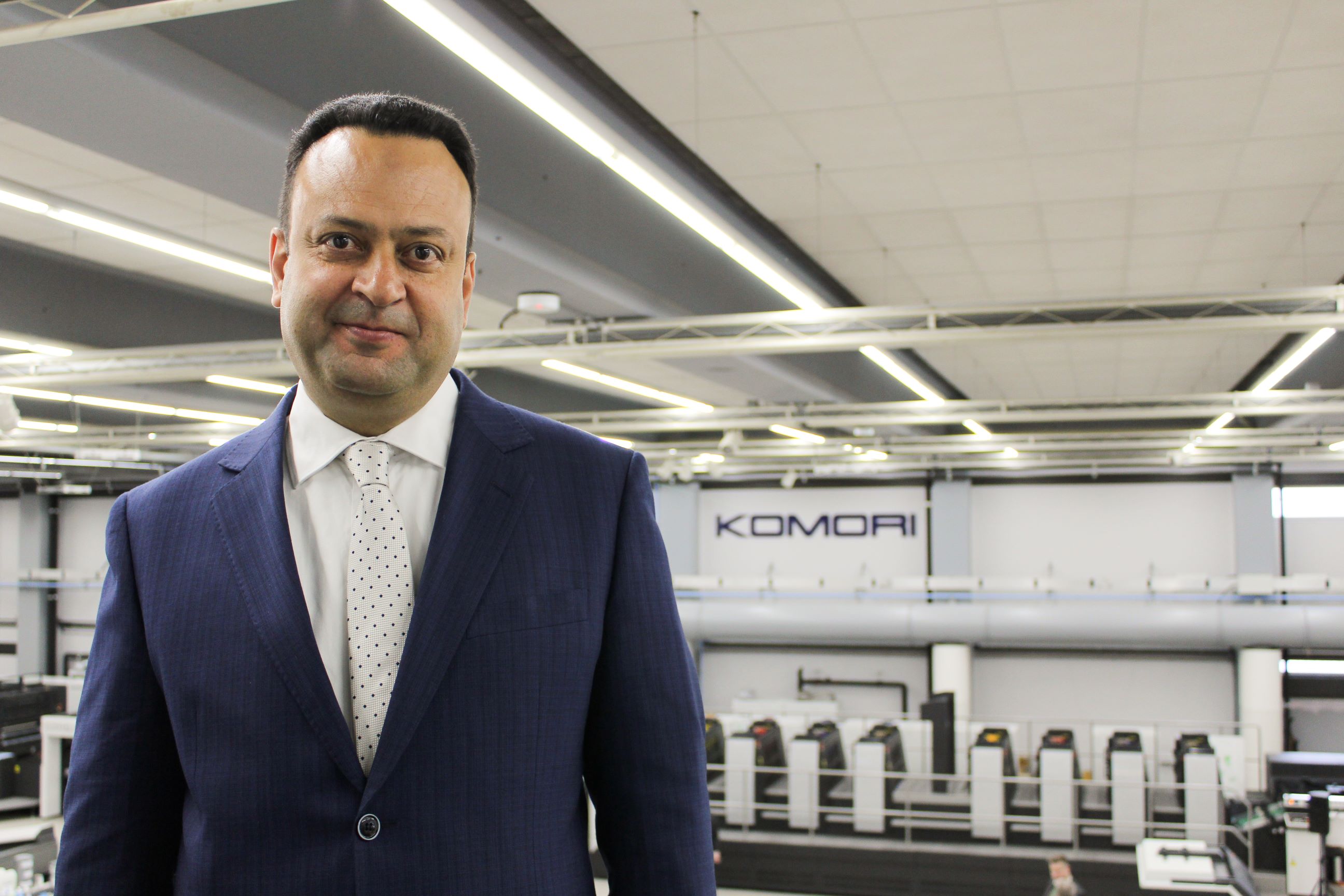

“The BOBST roadshow in Tunisia allowed converters to explore new opportunities for growth and operational excellence in all packaging segments,” said Eric Pavone, Regional Business Director for the AFRLAS region. “With a strong speaker program and strategic partner presence, the event perfectly showcased BOBST involvement and leadership in North Africa. And I’m pleased to report that the feedback has been overwhelmingly positive.”

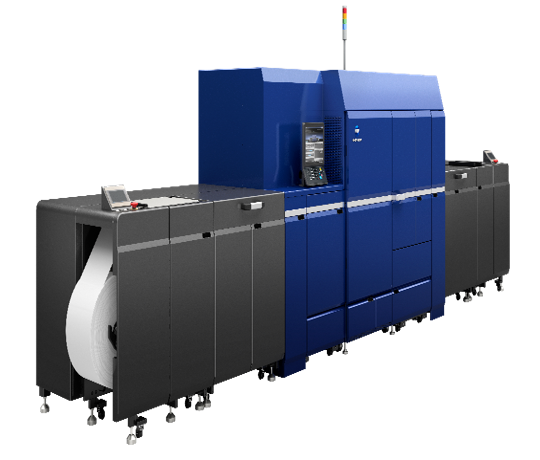

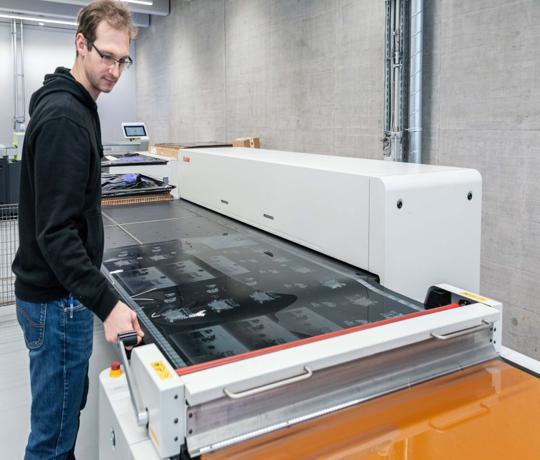

For the paperboard industry, the focus was on the new BOBST NOVAFFG flexo folder gluer. This complete box making solution, which has an optimized footprint and lean layout, offers a highly competitive price-performance ratio. The ETERNA portfolio of converting solutions was also presented as another cost-effective option for corrugated packaging. Folding carton specialists could learn about BOBST’s revolutionary Zero Fault Packaging concept, and the DIGITAL MASTER 55 All-in-One platform configured for light cartons.

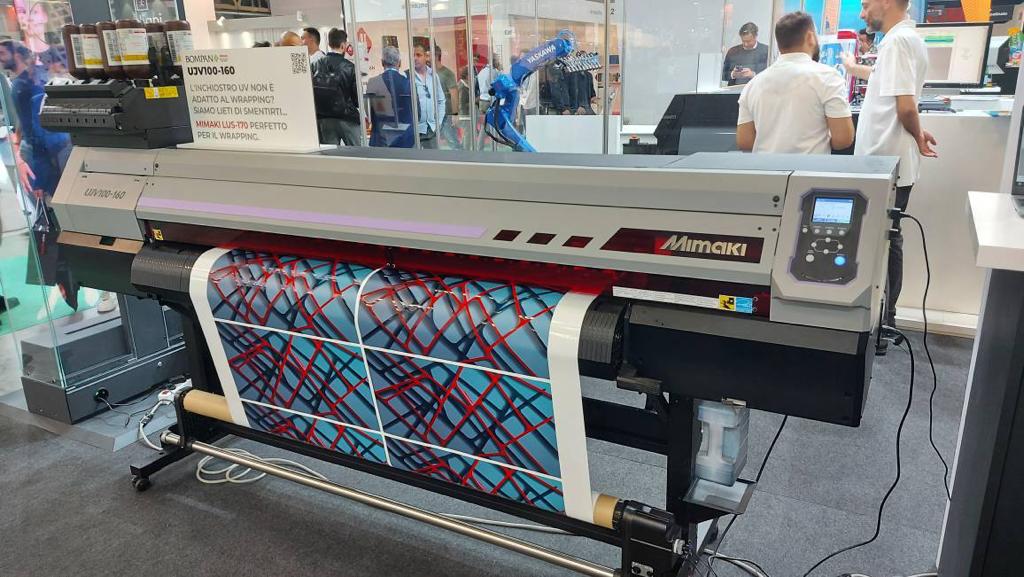

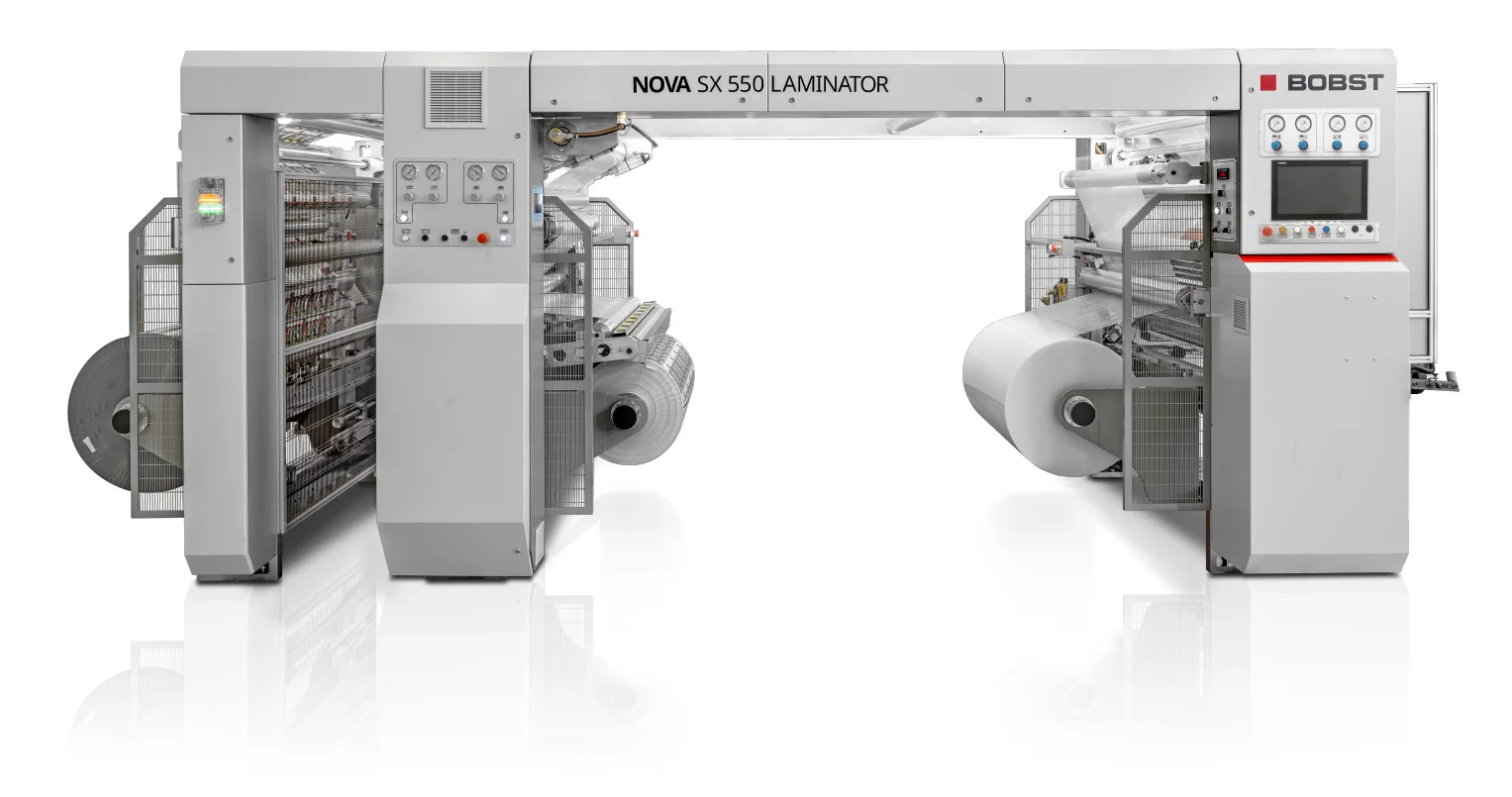

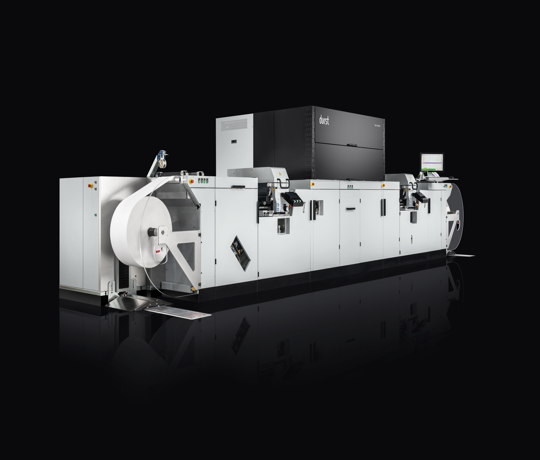

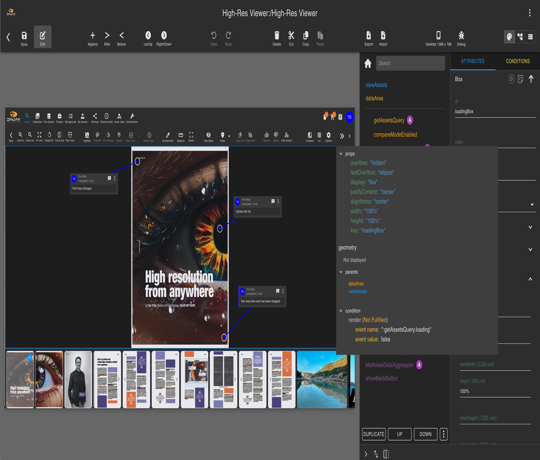

On the flexible packaging front, the modular VISION CI flexo press and multi-technology NOVALAM 800 laminator were in the spotlight, presenting a strong combination for efficient production. And for inline flexo labels, the star of the show was the MASTER M5, an automated versatile label and flexible packaging press. Other topics covered included BOBST Connect – the digital cloud-based platform, the digitalization of gravure printing, the latest innovations in coating and metallization, excellence in tooling performance, equipment financing solutions, and BOBST support & services.

Partner innovation and collaboration formed a big part of the program with talks from KURZ on new trends in digital embellishment and sustainable finishing, and innovation in gluing technology courtesy of Baumer HHS. PACKITOO HIPE, the AI-powered software that configures, calculates, and generates quotes, was also presented, while the Esko talk outlined the advantages of its collaboration with BOBST. The future of film extrusion was discussed by Reifenhäuser, and the challenges of sustainable innovation in printing equipment by Rossini.

.jpg)

.jpeg)

.jpg)

.png)

.jpg)

_hw13rw8.jpeg)

Recent Comments