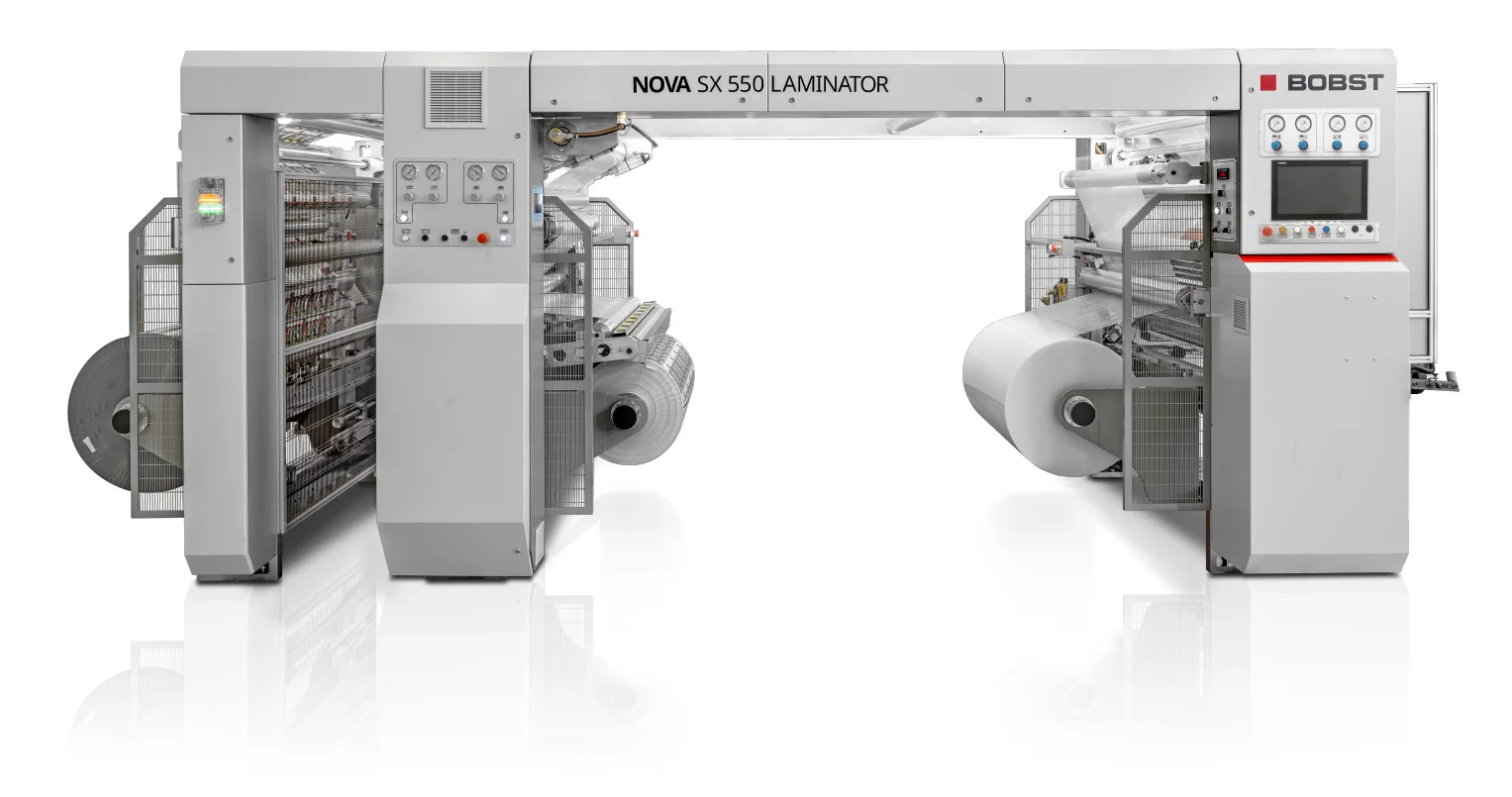

BOBST flies to number 1 in the world for vacuum metallizing…

Tetra Pak has once again been recognised for its continued transparency and action on environmental issues by CDP, the global environmental disclosure system. The company achieved an A- score for Forests, marking ten consecutive years in CDP’s leadership band (A or A-), and an A- score for Water Security for the third-year running.

This long-standing leadership on forests and water security is reinforced by the company’s Approach to Nature, a comprehensive framework introduced in 2024 to accelerate action across the value chain. The approach focusses on halting and reversing nature loss and enhancing water resilience through more than 20 measurable targets, spanning sourcing, operations, and collaboration with suppliers and customers. By addressing impacts upstream and downstream, and investing in restoration initiatives such as the Araucaria Conservation Project in Brazil, Tetra Pak aims to contribute to nature-positive food systems and global water security. It has already been recognised as industry leading-, earning the SEAL Business Sustainability Award for its Approach to Nature Framework.1 Tetra Pak also disclosed progress on climate change, receiving a B score from CDP. In 2024, Tetra Pak reduced greenhouse gas emissions across its own operations by 54% compared to a 2019 baseline, keeping on track to achieve net-zero by 2030. Across its value chain, emissions were cut by 25% versus baseline, a five percentage-point improvement on 2023.

Francesca Priora, Vice President Climate & Nature at Tetra Pak, said: “At Tetra Pak, we commit to making food safe and available, everywhere, and we cannot achieve this at the expense of our planet or people. Our approach to realising this ambition is rooted in concrete actions and measurable targets. Our continued presence in CDP’s leadership band for Forests and Water Security, along with our solid progress on climate actions, demonstrates our commitment to deliver on our ambitions in climate, nature, circularity, social sustainability, and food systems.

By building resilience across our industry, we aim to help shape a future where communities worldwide have safe access to nutrition while protecting the planet’s resources.”

_wrZSl8o_RRCJFlQ.gif)

.jpg)

.jpeg)

.jpg)

.png)

.jpg)

_hw13rw8.jpeg)

.jpg)

Recent Comments