ERP software for printing industry: Key benefits explained

Written by Pratik Shah, Creative Head - PrintXpand

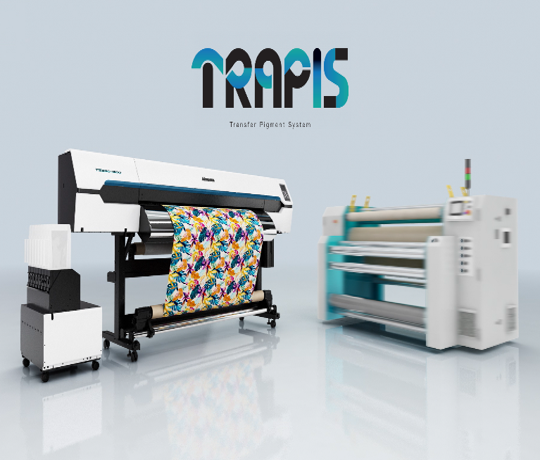

The printing industry work environment is very dynamic with accuracy, speed and control of cost playing major roles. The use of manual control over various print jobs, materials, machines and delivery schedules is prone to inefficiencies and errors. This is where the ERP for printing industry comes as a necessity and not fancy.

Enterprise Resource Planning systems designed specifically for print businesses help centralize operations, improve visibility, and streamline workflows. From job estimation and production scheduling to inventory control and invoicing, ERP software plays a vital role in transforming how print companies operate. In this blog, we explore the key benefits of ERP software for printing industry and explain why it is becoming a core requirement for modern print businesses.

Understanding ERP for Printing Industry

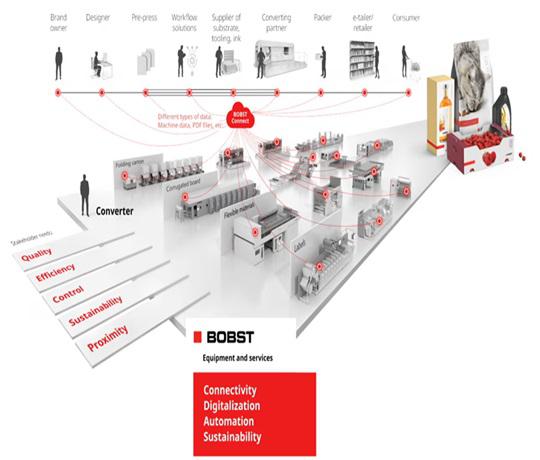

ERP for printing industry is the centralized software platform that brings all the main business functions of a printing company to one platform. As opposed to generic ERP systems, print focused ERP solutions are designed to support industry unique issues like variable job specification, quick turnaround, and sophisticated costing designs.

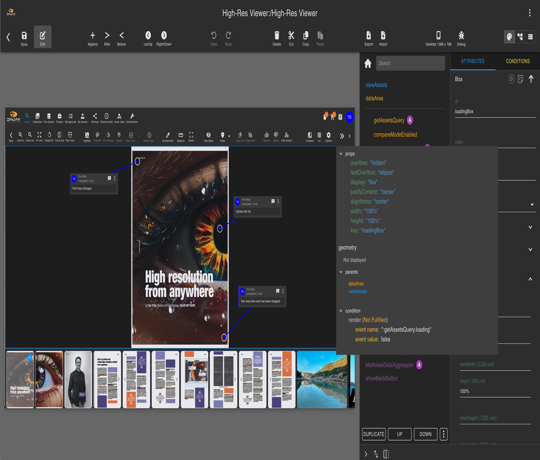

These systems often work alongside or integrate with print MIS software and web to print MIS platforms to create a seamless flow of data from order placement to final delivery. ERP systems bring together various departments within an organization such as sales, production, inventory, and finance hence providing consistency and transparency in operations.

Common Challenges Faced by Print Businesses

It is prudent to know the difficulties that print businesses encounter on a daily basis before learning the advantages of ERP software.

Most printing companies are using spreadsheets or disjointed software to track orders and production. This causes poor job costing, wastage of materials, late deliveries as well as the absence of real time visibility. Manual scheduling can lead to machine downtimes or production bottlenecks. Any type of inventory mismanagement may result in excess stock or even a sudden out-of-stock of key materials.

There is also the increased expectation of customers. Customers are pressuring them to deliver faster services, correct manufacturing costs and quality services. The inability to have a centralized system makes it harder and harder to live up to these expectations. This is where mis software for printing industry integrated with ERP brings significant value.

Key Benefits of ERP Software for Printing Industry

Streamlined Production Planning and Scheduling

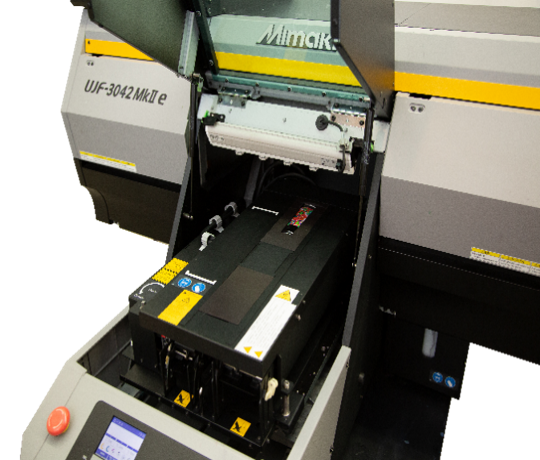

Enhanced production planning can be given as one of the most critical advantages of ERP for printing industry. The ERP systems enable print companies to schedule jobs according to the availability of machines, capacity of the workforce, and delivery dates.

ERP minimizes the wastage of time through automation of job sequencing and production schedules to maximize utilization of resources. Managers will be able to monitor the progress of the jobs real-time and make immediate changes when priorities are shifted. Such control assists print firms to print in time.

Accurate Job Costing and Quotation Management

Proper costing is a significant issue in the printing business because of the changes in the prices of materials and the different specifications of the jobs. ERP software for printing industry enables real time job costing by factoring in materials, labor, machine time, and overheads.

Using precise costing information, the sales teams are able to make accurate quotations within a short duration. This minimizes the chances of quoting the jobs at a lower cost or losing business on offers that take too long to respond to. Integrated print MIS software ensures that cost estimates align with actual production data, improving profitability.

Improved Inventory and Material Management

ERP systems give full access to the inventory stored in warehouses and production floors. Print businesses are able to monitor the raw materials e.g. paper, ink and plates in real time.

Stockouts can be prevented by automation of reorder alerts and waste can be minimized by proper monitoring of consumption. This becomes particularly useful when the quantity of print jobs, or even custom jobs is high. By integrating ERP with mis software for the printing industry, companies gain tighter control over material usage and inventory costs.

Enhanced Workflow Automation and Job Tracking

ERP software automates some of the repetitive jobs like creating jobs, approving workflow and updating the status. This minimizes the number of errors in manual processes and enhances efficiency in operations.

All departments operate on the same data which leads to improved coordination of the sales, production, and dispatch teams. Job tracking can be done in real time and is better at enhancing accountability and detecting early delays. When combined with web to print MIS, ERP creates a smooth flow from online order placement to production and delivery.

Better Order Management and Delivery Accuracy

Order management is a critical area where ERP software for printing industry delivers significant value. ERP systems trace all the order stages all the way through order entry and up to final dispatch.

This guarantees good order filling and prompt deliveries. The customers are constantly informed about the status of the orders, and this enhances transparency and confidence. Better customer relationships are also achieved because it results in increased accuracy on delivery and reduction of reprints and customer complaints.

Real Time Visibility and Reporting

ERP systems have centralized dashboards and reports which make the management have a clear picture of the business performance. Real time availability of metrics like job profitability, production efficiency, material consumption and delivery timelines are available.

This information based understanding assists decision makers to detect inefficiencies, manage expenses and strategize how money will be invested in the future. These insights can enable print businesses to scale operations in a strategic manner and react fast to market changes.

Quality Control and Process Consistency

It is paramount that the quality is kept with the printing industry. ERP software assists in the management of quality control through standardization of the workflow and keeping production records.

The system may have quality checkpoints that would guarantee adherence to the internal standards and customer demands. Past job information assists in correcting the common problems and enhancing processes in the long run. This leads to the reduction of reworks and customer satisfaction.

Improved Customer Satisfaction and Retention

The customers are direct beneficiaries when print business runs smoothly. The improved turnaround time, correct pricing and guaranteed delivery times improve the overall customer experience.

ERP system enhances interdepartmental communication which makes sure that the requirements of the customer are well understood and implemented. In the long-term this reliability creates long term relationships with customers as well as augmenting repeat business.

Conclusion

ERP for printing industry is now an important tool that businesses seek to implement in an attempt to enhance efficiency, cut costs and remain competitive. ERP software, by consolidating production planning, inventory management, job costing, and reporting, enhances the print operations, which previously were fragmented into different processes, into flowing operations. When combined with web to print MIS and print MIS software, ERP systems create a powerful digital foundation for growth and scalability.

The ERP solution will be of great help to print businesses intending to modernise operations and provide customers with steady value. PrintXpand can assist digital transformation of the printing industry by providing expertise in companies that aim to acquire advanced print technology solutions and integrate these systems with each other.

_wrZSl8o_RRCJFlQ.gif)

.jpg)

.jpeg)

.jpg)

.png)

.jpg)

_hw13rw8.jpeg)

.jpg)

Recent Comments